At Makeway Spring, we can custom design springs in various wire types, sizes, and materials to ensure your springs can accommodate any load. Whether you require a standard run of compression springs, we’re equipped to deliver them promptly in any quantity you need.

Carbon Steel Specifications: MK-65MN-CS01 、MK-65MN-CS02、MK-65MN-CS03、MK-65MN-CS04、MK-65MN-CS05、MK-65MN-CS06、MK-65MN-CS07、MK-65MN-CS08、MK-65MN-CS09、MK-65MN-CS10、MK-65MN-CS11

304 Stainless Steel Specifications: MK-304SS-CS01 、 MK-304SS-CS02 、 MK-304SS-CS03 、 MK-304SS-CS04

316 Stainless Steel Specifications: MK-316SS-CS01

Compression springs are used in valve springs, valve springs are a crucial component in internal combustion engines.

Compression springs are employed in battery compartments of electronic devices to maintain electrical contact between the battery and the device, ensuring a reliable power supply.

Compression springs are used in elevators to control the movement of the cab and counterweight for a smooth and controlled ride.

Compression springs are used to maintain proper tension in conveyor belts, ensuring smooth and consistent material flow.

We have the capability to provide our customers with custom compression springs to meet nearly any specification

Consistency is key in compression spring design. We craft high-quality conical springs and coils for superior deflection and extension. Any dimension, stock compression springs or a prototype of your own, we can build it for you. Our team is committed to quality from the time you click to get your free quote until the time we ship your product to you. We have the largest selection of compression springs and can produce the spring you need at the absolute highest quality.

At Makeway Spring ,we’re not just about springs;we’re all about quality.Our commitment to ensuring the highest standards for compression springs begins with comprehensive testing.From materials to dimensional accuracy and operational performance,we leave no stone unturned to guarantee your product’s excellence from the very start.

Material Testing:

Your best product deserves the finest materials. We offer a wide range of materials and test each one so that you can be sure your product is its best from start to finish.

Dimensional Accuracy:

Measuring is more than meets the eye. We use state of the art measuring tools to ensure accuracy down to the micrometer.

Operational Testing:

Before we even consider shipping your springs to you, each one is subjected to rigorous testing at each point in the production process, guaranteeing each one will perform at the highest level.

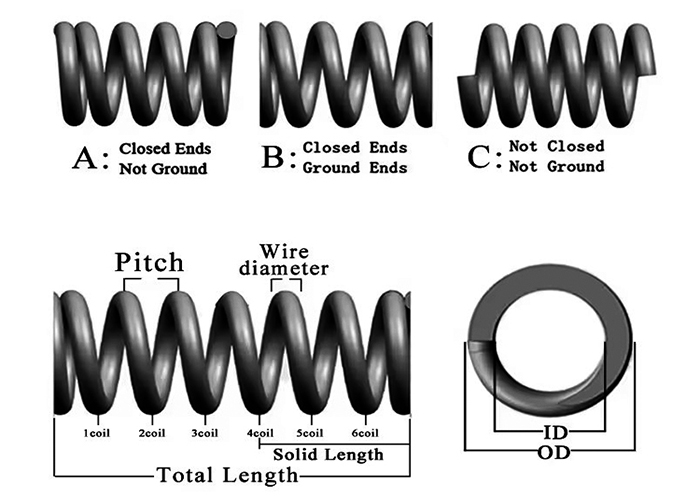

From the type of material to the diameter and end types, we have what you need to create your custom springs to ensure optimal performance. If you don’t have exactly what you need in the springs in stock – choose our custom manufacturing services and get the perfect solution for your unique situation.

We specialize in custom compression springs to ensure that we can meet our customer’s every desired parameter.We know that finding the perfect compression springs may be a daunting task,but we are here to help. Just click below for your free quote.

Compression springs are designed to create resistance to a compressive force.We’ve helped companies design, test,and manufacture compression springs for a wide variety of industries.Reach out to one of our engineers today and let’s get your project started.

Common materials for compression springs include stainless steel and music wire. Each material has specific properties that make it suitable for different applications. We offer any material you need and use only the highest quality materials for your application.

Compression springs find applications in various fields such as engineering, music, automotive, aerospace, and more. Any type or application you need, we can supply it.

We offer an endless variety of compression springs, both in standard configurations and custom-made so you get exactly the wire spring you need.

To find the right compression spring, consider factors like dimensions, load capacity, deflection requirements, and environment. If you have any questions, feel free to contact us at any time.

We have many stock compression springs ready to ship, ensuring prompt delivery. Custom springs may have a lead time based on specific design and manufacturing requirements.

While compression springs are versatile, they do have limitations. Factors like maximum load, deflection, and material types should be considered to ensure optimal performance and longevity.

From the initial spring design to the manufacturing and delivery.Our best practices and quality assurance ensure you end up with the precise parts made just for your project. Every solution is designed for your needs.

Compression springs are a common type of spring designed to resist compressive forces. These springs are typically coiled and are widely used in applications like automotive suspensions, industrial machinery, and electronic devices.

Die springs are designed for high-load applications, commonly used in stamping dies and die sets. These springs are usually made of high-strength alloy steel, providing greater resistance to compression and longer service life.

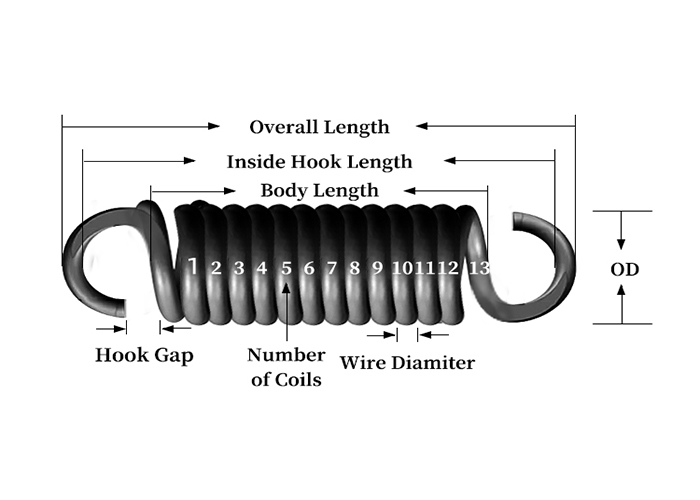

Tension springs store energy when stretched and return to their original shape when released. They are commonly used in applications such as door locks, toys, and mechanical devices. Tension springs typically have hooks on both ends for attachment.

Headless tension springs are similar to regular tension springs but lack traditional hooks or ends. These springs are used in applications requiring specific attachment methods to meet design requirements.

Clock springs, also known as mainsprings, are coiled springs used to store mechanical energy. They are widely used in clocks, toys, and other devices that require energy storage. These springs can be wound manually or mechanically and then release energy to power mechanical devices.

Torsion springs are designed to withstand torque or rotational force. These springs are commonly used in clips, switches, garage doors, and other devices where rotational force is applied, providing a counteracting force by twisting.

Brass springs are made from brass material, offering excellent corrosion resistance and electrical conductivity. They are often used in applications requiring corrosion resistance or electrical conductivity, such as electrical switches and terminals.

Wire forming include various springs and parts formed by bending metal wire into shapes. These are custom-designed for specific applications and can be made into complex shapes to fit unique mechanical or electronic devices.

Obtain firsthand quotes and product information; we are available 24/7 to assist you with any inquiries.

info@makeway-llc.com

+86 755 28459980

Room 1510, Building 13 Huanancheng, No.1 Ping'an Avenue, Longgang District, Shenzhen, Guangdong, China