At Makeway Spring, we have experience with all types of die springs. All our springs are built to the highest standards to operate above industry standards and are used in machinery including farm machinery and 3D printing.

Carbon Steel Specifications: MK-65MN-DS01 、MK-65MN-DS02、MK-65MN-DS03、MK-65MN-DS04、MK-65MN-DS05

Alloy Specifications: MK-AS-DS01 、MK-AS-DS02、MK-AS-DS03、MK-AS-DS04、MK-AS-DS05

Factors that are important while choosing which die spring is best for your project:

By purchasing through Makeway Spring you will have the best product for various applications.Contact us at any time and one of our customer service team members can help you out with your custom order or request an estimate below.

We have the capability to provide our customers with custom compression springs to meet nearly any specification

In the world of heavy machinery and industrial applications,precision is paramount.At Makeway Spring,our die springs undergo rigorous testing to guarantee impeccable performance.

In the world of heavy machinery and industrial applications,precision is paramount.At Makeway Spring,our die springs undergo rigorous testing to guarantee impeccable performance.

Load Testing:

This test involves subjecting the die spring to different loads to verify that it can compress and return to its original position without deformation or failure. It ensures that the spring can handle the expected loads in the application.

Deflection Testing:

This test measures the spring’s deflection under a specified load. It helps determine the spring’s behavior when subjected to a particular force and ensures it meets the design requirements.

Stress and Strain Testing:

This involves evaluating the spring’s response to applied stress. It helps determine the spring’s elastic and plastic deformation behavior and ensures it can handle the expected working conditions.

Material Analysis:

Testing the material properties of the spring, including tensile strength, yield strength, and composition, ensures it meets the specified standards for the application.

Die Spring design is not always one-size-fits-all. We at Makeway Spring pride ourselves on having the best engineers and top-notch customer service. No other manufacturer will offer you better service and when you need custom springs made, our team is clutch. We work hard so you can be sure your custom heavy duty metal Die springs.

ie springs,built for heavy machinery,use high-quality alloyed steel for superior load-bearing.Essential for industrial machines,proper selection and maintenance are key for longevity.They come in various configurations to suit different needs.

Die springs are heavy-duty compression springs that are commonly used in die machinery,stamping presses, and other heavy-duty industrial applications.They are designed to withstand high load and provide reliable and consistent performance.

Die springs offer several benefits,including high load-bearing capacity,long service life,efficient energy absorption,and resistance to fatigue and wear.They provide consistent force throughout their working range and are available in various sizes and force ratings to meet specific application requirements.

When selecting a die spring,you need to consider factors such as the required load capacity,working environment conditions, spring size and type,and the desired deflection and force specifications.It is recommended to consult with a spring manufacturer or engineer to ensure you choose the right spring for your application.

Die springs are often color-coded to distinguish between different force ratings.The commonly used color codes are lightest load (blue), light load (yellow),medium load (red), heavy load (green),extra-heavy load (brown), and ultra-heavy load (purple).

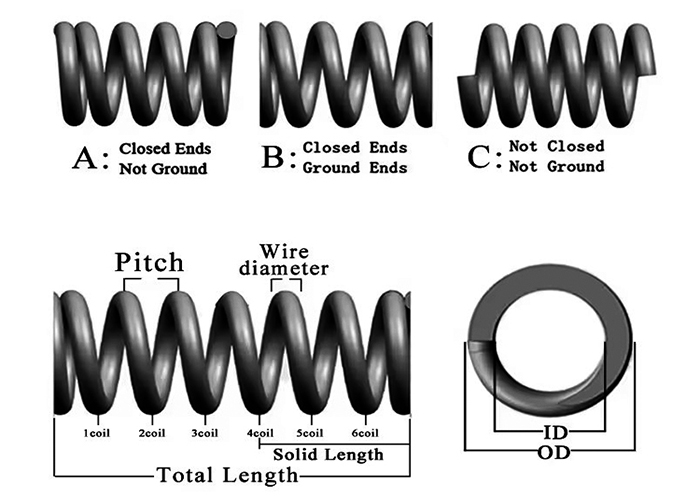

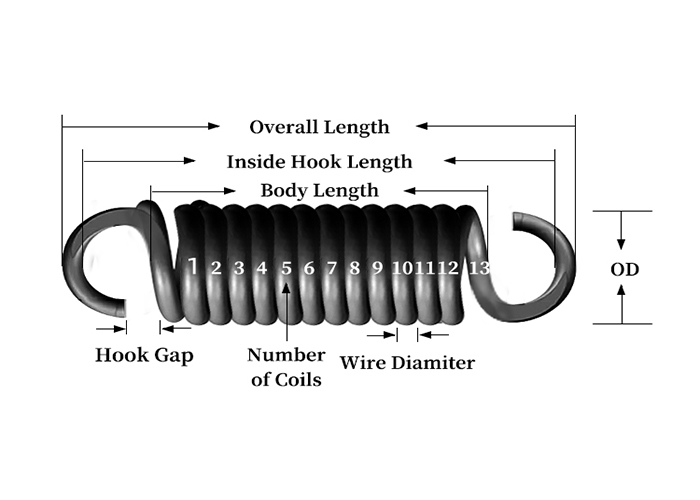

Yes, die springs can be customized to meet specific load capacities,sizes,and force specifications.Customization options include altering the outer diameter,inner diameter,wire size,and length to suit your application needs.

The lifespan of die springs depends on several factors,such as the application’s operating conditions,load profile,and proper maintenance.However, die springs are designed to have a long service life and can withstand millions of cycles under normal operating conditions.

Die springs are primarily designed for heavy-duty industrial applications.While they may be used in some non-industrial applications,it is recommended to consult with a spring manufacturer or engineer to determine the suitability of die springs for your specific application.

Yes,Makeway Spring can handle orders of all sizes,from small to large.Whether you need a single die spring or a large quantity for your production line,we can provide customized solutions to meet your specific needs.

From the initial spring design to the manufacturing and delivery.Our best practices and quality assurance ensure you end up with the precise parts made just for your project. Every solution is designed for your needs.

Compression springs are a common type of spring designed to resist compressive forces. These springs are typically coiled and are widely used in applications like automotive suspensions, industrial machinery, and electronic devices.

Die springs are designed for high-load applications, commonly used in stamping dies and die sets. These springs are usually made of high-strength alloy steel, providing greater resistance to compression and longer service life.

Tension springs store energy when stretched and return to their original shape when released. They are commonly used in applications such as door locks, toys, and mechanical devices. Tension springs typically have hooks on both ends for attachment.

Headless tension springs are similar to regular tension springs but lack traditional hooks or ends. These springs are used in applications requiring specific attachment methods to meet design requirements.

Clock springs, also known as mainsprings, are coiled springs used to store mechanical energy. They are widely used in clocks, toys, and other devices that require energy storage. These springs can be wound manually or mechanically and then release energy to power mechanical devices.

Torsion springs are designed to withstand torque or rotational force. These springs are commonly used in clips, switches, garage doors, and other devices where rotational force is applied, providing a counteracting force by twisting.

Brass springs are made from brass material, offering excellent corrosion resistance and electrical conductivity. They are often used in applications requiring corrosion resistance or electrical conductivity, such as electrical switches and terminals.

Wire forming include various springs and parts formed by bending metal wire into shapes. These are custom-designed for specific applications and can be made into complex shapes to fit unique mechanical or electronic devices.

Obtain firsthand quotes and product information; we are available 24/7 to assist you with any inquiries.

info@makeway-llc.com

+86 755 28459980

Room 1510, Building 13 Huanancheng, No.1 Ping'an Avenue, Longgang District, Shenzhen, Guangdong, China