Whatever counter balance spring product you need, our experienced work force and dedicated support staff is at your service.

With decades of experience as a spring manufacturer and state-of-the-art equipment and tools, we at Makeway Spring have the capability to handle your project from design to out the door quickly and at the highest level of quality. Whether your application is mechanical or industrial, we can meet your needs.

Carbon Steel Specifications: MK-65MN-CL01 、MK-65MN-CL02 、MK-65MN-CL03

Clock springs serve as the primary power source for watches, storing energy and gradually releasing it to keep the hands moving continuously.

In wind-up toys,clock springs store energy when wound,which is released to produce motion in the toy.

Clock springs provide the pulling force needed for smooth operation of roll-up doors and help maintain the position of blinds.

Used in car seats or office chairs to provide the adjustment force for height or angle positioning.

In some automated production lines,clock springs are used to provide rotational power or reset functions.

We have the capability to provide our customers with custom clock springs to meet nearly any specification

Whatever end product you need,any length or size,our commitment to quality means that your brand is in good hands.We take the pressure off you by adhering to the highest standards so you can rest assured that your springs come out perfect.

We use the most advanced tools to test clock spring to ensure they perfectly match your manufacturing project.

Prueba de materiales:

We test to verify the composition and quality of materials before we even start making your product. Our commitment to quality custom springs starts with quality materials.

Precisión dimensional:

We always test for dimensional accuracy to the smallest unit to ensure that, large or small, your lot of product is dimensionally ideal.

Pruebas operativas:

You want your springs to function at the highest level.We here at Makeway Spring use meticulous testing to ensure each spring meets or exceeds your requirements.

If you have a unique application that requires a specialized spring,we have a solution to fit your needs.At Makeway Spring,we don’t just sell springs,we also sell a service.

Our team is dedicated to helping you find the right clock spring for your needs and providing you with the customer support you need to get the job done right. We offer fast and reliable shipping, so you can get your custom clock springs on time every time.

Whether your business is big or small, we have the clock spring solution for you. Contact us today to learn more about our clock springs and how we can take care of your specific needs.

Whatever counter balance spring product you need, our experienced work force and dedicated support staff is at your service.

A clockwork spring, also known as a power spring,is a type of flat metal strip that is coiled in a spiral shape and is capable of storing and releasing energy.It stores energy through rotational movement and releases it to provide continuous rotational force,commonly used in devices requiring sustained power.

Clockwork spring store mechanical energy by coiling tighter when rotational force is applied.When released,the spring uncoils and releases the stored energy,producing continuous rotational movement or driving force.

The force a clock spring can handle depends on its material, thickness,and design. Manufacturers typically provide specific load capacities to ensure safe operation within the designed load limits.

Yes,clock springs can be customized in terms of size,material,and load capacity to suit specific mechanical devices or applications.

The quality of a clock spring can be judged by its material, surface treatment,elasticity,and load capacity. If the spring loses its elasticity or shows signs of fatigue,it may need to be replaced.

Desde el diseño inicial del resorte hasta la fabricación y la entrega, nuestras mejores prácticas y control de calidad garantizan que recibirá las piezas precisas, hechas a medida para su proyecto. Cada solución está diseñada para satisfacer sus necesidades.

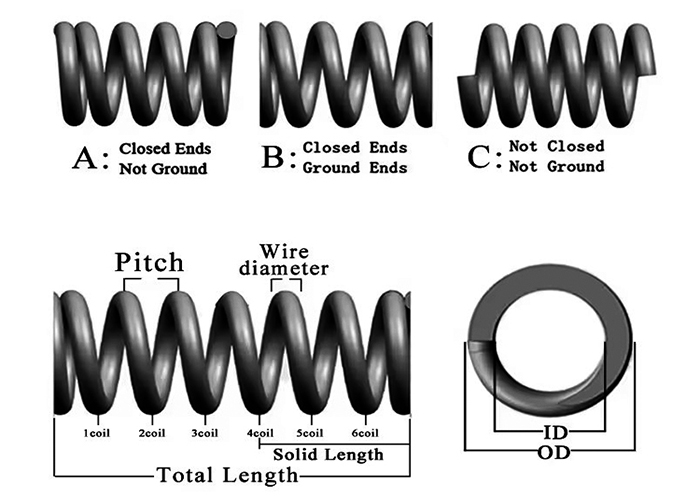

Los resortes de compresión son un tipo común de resorte diseñado para resistir fuerzas de compresión. Estos resortes suelen estar enrollados y se utilizan ampliamente en aplicaciones como suspensiones de automóviles, maquinaria industrial y dispositivos electrónicos.

Los resortes para matrices están diseñados para aplicaciones de alta carga y se utilizan comúnmente en matrices y juegos de matrices de estampación. Estos resortes suelen estar fabricados con acero de aleación de alta resistencia, lo que proporciona mayor resistencia a la compresión y una mayor vida útil.

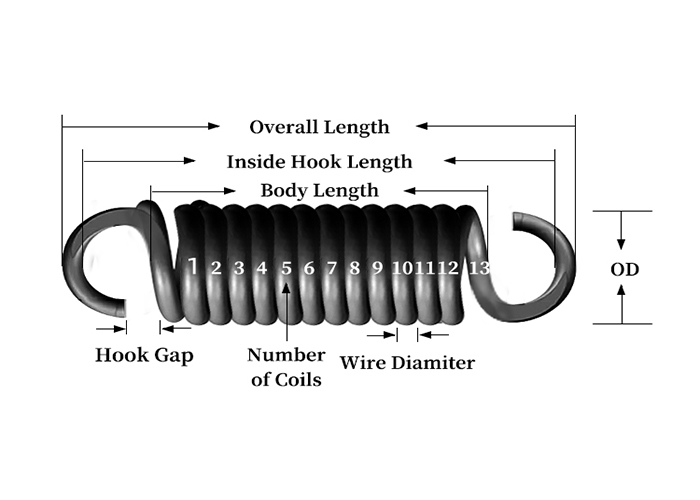

Los resortes de tensión almacenan energía al estirarse y recuperan su forma original al soltarse. Se utilizan comúnmente en aplicaciones como cerraduras de puertas, juguetes y dispositivos mecánicos. Suelen tener ganchos en ambos extremos para su fijación.

Los resortes de tensión sin cabeza son similares a los resortes de tensión convencionales, pero carecen de ganchos o extremos tradicionales. Estos resortes se utilizan en aplicaciones que requieren métodos de fijación específicos para cumplir con los requisitos de diseño.

Los resortes de reloj, también conocidos como resortes reales, son resortes helicoidales que se utilizan para almacenar energía mecánica. Se utilizan ampliamente en relojes, juguetes y otros dispositivos que requieren almacenamiento de energía. Estos resortes pueden enrollarse manual o mecánicamente y luego liberan energía para alimentar dispositivos mecánicos.

Los resortes de torsión están diseñados para soportar torsión o fuerza de rotación. Estos resortes se utilizan comúnmente en clips, interruptores, puertas de garaje y otros dispositivos donde se aplica fuerza de rotación, proporcionando una fuerza contrarrestante mediante torsión.

Los resortes de latón están hechos de latón, lo que ofrece excelente resistencia a la corrosión y conductividad eléctrica. Se utilizan a menudo en aplicaciones que requieren resistencia a la corrosión o conductividad eléctrica, como interruptores y terminales eléctricos.

El conformado de alambre incluye diversos resortes y piezas que se forman doblando alambre metálico. Estos se diseñan a medida para aplicaciones específicas y pueden fabricarse en formas complejas para adaptarse a dispositivos mecánicos o electrónicos únicos.

Obtenga cotizaciones de primera mano e información de productos; estamos disponibles las 24 horas, los 7 días de la semana para ayudarlo con cualquier consulta.

info@makeway-llc.com

+86 755 28459980

Habitación 1510, Edificio 13, Huanancheng, Avenida Ping'an n.° 1, Distrito de Longgang, Shenzhen, Guangdong, China