In a fast-paced world, torsion springs are a vital component in many industries.

Their versatility and ability to store and release energy make them indispensable components in countless mechanical systems across different sectors.

Single Torsion Spring: MK-65MN-TS01 、MK-65MN-TS02

Double Torsion Spring: MK-65MN-TS03 、MK-65MN-TS04 、MK-65MN-TS05 、MK-65MN-TS06 、MK-65MN-TS07 、MK-65MN-TS08 、MK-65MN-TS09、MK-65MN-TS10 、MK-65MN-TS11 、MK-65MN-TS12 、MK-65MN-TS13 、MK-65MN-TS14 、MK-65MN-TS15 、MK-65MN-TS16 、MK-65MN-TS17 、MK-65MN-TS18

Custom-Shaped Torsion Spring: MK-65MN-TS19、MK-65MN-TS20、MK-65MN-TS21

Torsion springs are commonly used in automatic return door hinge systems,helping doors open and close smoothly while maintaining the desired position.

Torsion springs provide clamping force in items like clothespins and various clamps,holding objects securely in place.

Used in car doors,trunk lids, and other components that require a return function,such as seat angle adjusters.

Torsion springs are used in reset functions for electrical devices,such as camera shutters,clocks, and switches.

Torsion springs are employed in many spring-driven toys and devices to produce rotational movement or provide a return function.

We have the capability to provide our customers with custom torsion springs to meet nearly any specification

Reliable torsion spring operation requires the highest quality materials,precise machining,and efficient processes.Our state-of-the-art manufacturing facility,personal touch,and expertise ensure that your springs meet your exact specifications.Torsion springs are known for their reliability,and you can rely on us to bring your vision to life.

Prueba de materiales:

Although we use only the finest spring materials, we take nothing for granted. Every spring must meet our meticulous testing standards.

Precisión dimensional:

We measure down to the micrometer to ensure the dimensional accuracy that your product requires to not just meet operational standards, but exceed them.

Pruebas operativas:

We subject each spring to rigorous testing to ensure optimum performance and consistency.

Quality Assurance:

Our QA department is committed to delivering excellence and providing top-of-the-line quality products.

If you need a custom spring, our experts can help you design it. Your needs may depend on your industry,target market,or other factors.Whatever your particular needs,we can supply them at the highest level.

Ensuring a torsion spring’s compliance to your specifications requires a personal touch.We pride ourselves on working directly with you to make sure that your custom springs meet every requirement,every time. When quality and personal service come together,your custom springs come out right.

Our commitment to quality and service continues from product inception to the final roll-out of your torsion spring application.Have questions?We are here to help whether you are looking to R&D a single design or get a full line of products.Whatever your needs,our manufacturing capabilities deliver. Feel free to click below to get started.

We make torsion springs of any type or size that can serve a variety of industries.

A torsion spring, also known as a torque spring,is a type of coiled spring designed to store and release rotational force.When an external force is applied,the spring generates torque,and when released, it returns to its original position,providing return or rotational force.

The design of a torsion spring, including wire diameter,number of coils,arm length,and angle of rotation,directly impacts the torque it can provide and its working angle.These parameters can be adjusted to meet different mechanical requirements depending on the application.

Yes,torsion springs can be customized.Manufacturers can design and produce springs based on specific torque requirements,working angles,and space constraints provided by the customer

The manufacturing time can vary depending on the complexity and quantity of the order. However,Makeway Spring is known for its efficient production process, and we strive to deliver your springs within the agreed upon time frame.

Yes, Makeway Spring provides various finishing options for torsion springs,including heat treatment, plating,powder coating,and more,to enhance their durability and appearance.

The lifespan of a torsion spring depends on its material,usage frequency,load,and working environment.With proper design and maintenance,high-quality torsion springs can last for hundreds of thousands of cycles or even longer.

Of course,we have two warehouses in the United States. Whether you're located in the U.S. or Canada,Makeway Spring can deliver your torsion springs directly to your doorstep.

Desde el diseño inicial del resorte hasta la fabricación y la entrega, nuestras mejores prácticas y control de calidad garantizan que recibirá las piezas precisas, hechas a medida para su proyecto. Cada solución está diseñada para satisfacer sus necesidades.

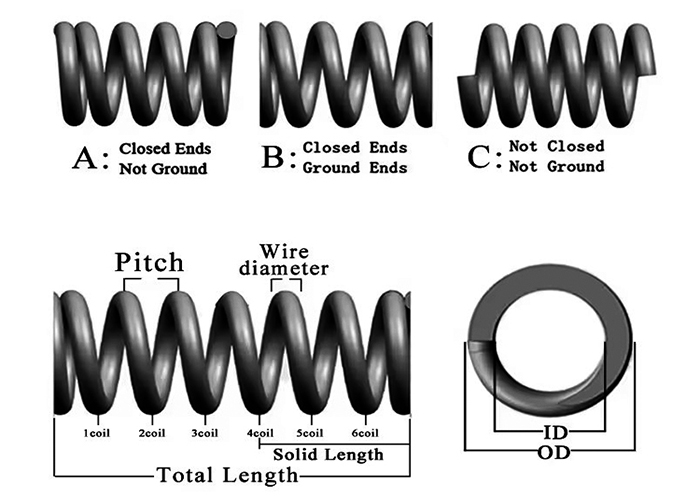

Los resortes de compresión son un tipo común de resorte diseñado para resistir fuerzas de compresión. Estos resortes suelen estar enrollados y se utilizan ampliamente en aplicaciones como suspensiones de automóviles, maquinaria industrial y dispositivos electrónicos.

Los resortes para matrices están diseñados para aplicaciones de alta carga y se utilizan comúnmente en matrices y juegos de matrices de estampación. Estos resortes suelen estar fabricados con acero de aleación de alta resistencia, lo que proporciona mayor resistencia a la compresión y una mayor vida útil.

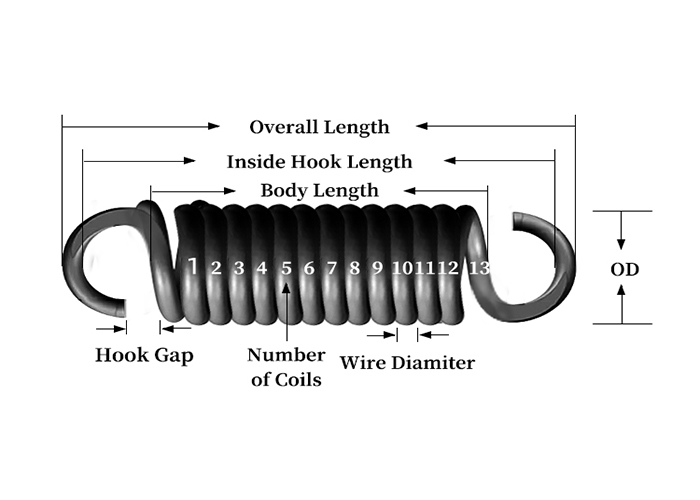

Los resortes de tensión almacenan energía al estirarse y recuperan su forma original al soltarse. Se utilizan comúnmente en aplicaciones como cerraduras de puertas, juguetes y dispositivos mecánicos. Suelen tener ganchos en ambos extremos para su fijación.

Los resortes de tensión sin cabeza son similares a los resortes de tensión convencionales, pero carecen de ganchos o extremos tradicionales. Estos resortes se utilizan en aplicaciones que requieren métodos de fijación específicos para cumplir con los requisitos de diseño.

Los resortes de reloj, también conocidos como resortes reales, son resortes helicoidales que se utilizan para almacenar energía mecánica. Se utilizan ampliamente en relojes, juguetes y otros dispositivos que requieren almacenamiento de energía. Estos resortes pueden enrollarse manual o mecánicamente y luego liberan energía para alimentar dispositivos mecánicos.

Los resortes de torsión están diseñados para soportar torsión o fuerza de rotación. Estos resortes se utilizan comúnmente en clips, interruptores, puertas de garaje y otros dispositivos donde se aplica fuerza de rotación, proporcionando una fuerza contrarrestante mediante torsión.

Los resortes de latón están hechos de latón, lo que ofrece excelente resistencia a la corrosión y conductividad eléctrica. Se utilizan a menudo en aplicaciones que requieren resistencia a la corrosión o conductividad eléctrica, como interruptores y terminales eléctricos.

El conformado de alambre incluye diversos resortes y piezas que se forman doblando alambre metálico. Estos se diseñan a medida para aplicaciones específicas y pueden fabricarse en formas complejas para adaptarse a dispositivos mecánicos o electrónicos únicos.

Obtenga cotizaciones de primera mano e información de productos; estamos disponibles las 24 horas, los 7 días de la semana para ayudarlo con cualquier consulta.

info@makeway-llc.com

+86 755 28459980

Habitación 1510, Edificio 13, Huanancheng, Avenida Ping'an n.° 1, Distrito de Longgang, Shenzhen, Guangdong, China