At Makeway Spring, we have experience with all types of die springs. All our springs are built to the highest standards to operate above industry standards and are used in machinery including farm machinery and 3D printing.

Carbon Steel Specifications: MK-65MN-DS01 、MK-65MN-DS02、MK-65MN-DS03、MK-65MN-DS04、MK-65MN-DS05

Alloy Specifications: MK-AS-DS01 、MK-AS-DS02、MK-AS-DS03、MK-AS-DS04、MK-AS-DS05

Factors that are important while choosing which die spring is best for your project:

By purchasing through Makeway Spring you will have the best product for various applications.Contact us at any time and one of our customer service team members can help you out with your custom order or request an estimate below.

Tenemos la capacidad de proporcionar a nuestros clientes resortes de compresión personalizados para cumplir con casi cualquier especificación.

In the world of heavy machinery and industrial applications,precision is paramount.At Makeway Spring,our die springs undergo rigorous testing to guarantee impeccable performance.

In the world of heavy machinery and industrial applications,precision is paramount.At Makeway Spring,our die springs undergo rigorous testing to guarantee impeccable performance.

Load Testing:

This test involves subjecting the die spring to different loads to verify that it can compress and return to its original position without deformation or failure. It ensures that the spring can handle the expected loads in the application.

Deflection Testing:

This test measures the spring’s deflection under a specified load. It helps determine the spring’s behavior when subjected to a particular force and ensures it meets the design requirements.

Stress and Strain Testing:

This involves evaluating the spring’s response to applied stress. It helps determine the spring’s elastic and plastic deformation behavior and ensures it can handle the expected working conditions.

Material Analysis:

Testing the material properties of the spring, including tensile strength, yield strength, and composition, ensures it meets the specified standards for the application.

Die Spring design is not always one-size-fits-all. We at Makeway Spring pride ourselves on having the best engineers and top-notch customer service. No other manufacturer will offer you better service and when you need custom springs made, our team is clutch. We work hard so you can be sure your custom heavy duty metal Die springs.

ie springs,built for heavy machinery,use high-quality alloyed steel for superior load-bearing.Essential for industrial machines,proper selection and maintenance are key for longevity.They come in various configurations to suit different needs.

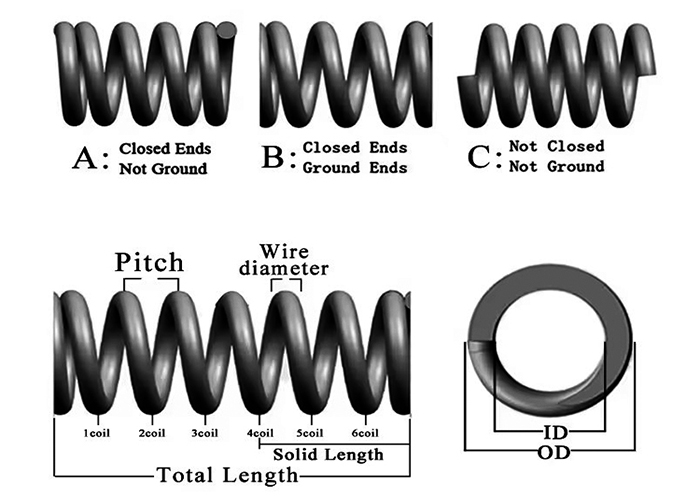

Die springs are heavy-duty compression springs that are commonly used in die machinery,stamping presses, and other heavy-duty industrial applications.They are designed to withstand high load and provide reliable and consistent performance.

Die springs offer several benefits,including high load-bearing capacity,long service life,efficient energy absorption,and resistance to fatigue and wear.They provide consistent force throughout their working range and are available in various sizes and force ratings to meet specific application requirements.

When selecting a die spring,you need to consider factors such as the required load capacity,working environment conditions, spring size and type,and the desired deflection and force specifications.It is recommended to consult with a spring manufacturer or engineer to ensure you choose the right spring for your application.

Die springs are often color-coded to distinguish between different force ratings.The commonly used color codes are lightest load (blue), light load (yellow),medium load (red), heavy load (green),extra-heavy load (brown), and ultra-heavy load (purple).

Yes, die springs can be customized to meet specific load capacities,sizes,and force specifications.Customization options include altering the outer diameter,inner diameter,wire size,and length to suit your application needs.

The lifespan of die springs depends on several factors,such as the application’s operating conditions,load profile,and proper maintenance.However, die springs are designed to have a long service life and can withstand millions of cycles under normal operating conditions.

Die springs are primarily designed for heavy-duty industrial applications.While they may be used in some non-industrial applications,it is recommended to consult with a spring manufacturer or engineer to determine the suitability of die springs for your specific application.

Yes,Makeway Spring can handle orders of all sizes,from small to large.Whether you need a single die spring or a large quantity for your production line,we can provide customized solutions to meet your specific needs.

Desde el diseño inicial del resorte hasta la fabricación y la entrega, nuestras mejores prácticas y control de calidad garantizan que recibirá las piezas precisas, hechas a medida para su proyecto. Cada solución está diseñada para satisfacer sus necesidades.

Los resortes de compresión son un tipo común de resorte diseñado para resistir fuerzas de compresión. Estos resortes suelen estar enrollados y se utilizan ampliamente en aplicaciones como suspensiones de automóviles, maquinaria industrial y dispositivos electrónicos.

Los resortes para matrices están diseñados para aplicaciones de alta carga y se utilizan comúnmente en matrices y juegos de matrices de estampación. Estos resortes suelen estar fabricados con acero de aleación de alta resistencia, lo que proporciona mayor resistencia a la compresión y una mayor vida útil.

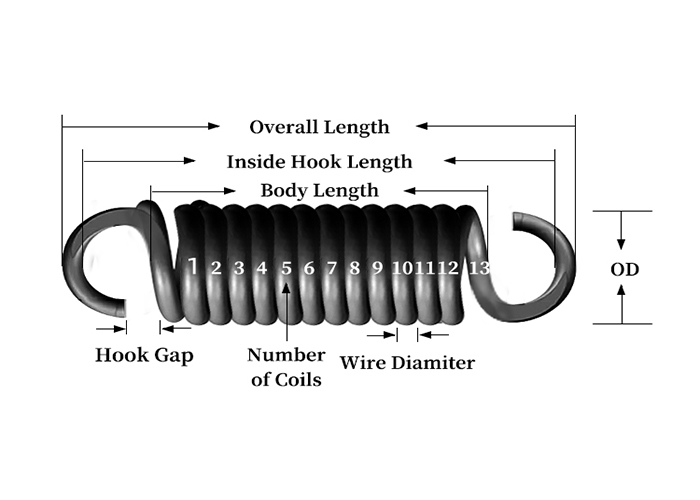

Los resortes de tensión almacenan energía al estirarse y recuperan su forma original al soltarse. Se utilizan comúnmente en aplicaciones como cerraduras de puertas, juguetes y dispositivos mecánicos. Suelen tener ganchos en ambos extremos para su fijación.

Los resortes de tensión sin cabeza son similares a los resortes de tensión convencionales, pero carecen de ganchos o extremos tradicionales. Estos resortes se utilizan en aplicaciones que requieren métodos de fijación específicos para cumplir con los requisitos de diseño.

Los resortes de reloj, también conocidos como resortes reales, son resortes helicoidales que se utilizan para almacenar energía mecánica. Se utilizan ampliamente en relojes, juguetes y otros dispositivos que requieren almacenamiento de energía. Estos resortes pueden enrollarse manual o mecánicamente y luego liberan energía para alimentar dispositivos mecánicos.

Los resortes de torsión están diseñados para soportar torsión o fuerza de rotación. Estos resortes se utilizan comúnmente en clips, interruptores, puertas de garaje y otros dispositivos donde se aplica fuerza de rotación, proporcionando una fuerza contrarrestante mediante torsión.

Los resortes de latón están hechos de latón, lo que ofrece excelente resistencia a la corrosión y conductividad eléctrica. Se utilizan a menudo en aplicaciones que requieren resistencia a la corrosión o conductividad eléctrica, como interruptores y terminales eléctricos.

El conformado de alambre incluye diversos resortes y piezas que se forman doblando alambre metálico. Estos se diseñan a medida para aplicaciones específicas y pueden fabricarse en formas complejas para adaptarse a dispositivos mecánicos o electrónicos únicos.

Obtenga cotizaciones de primera mano e información de productos; estamos disponibles las 24 horas, los 7 días de la semana para ayudarlo con cualquier consulta.

info@makeway-llc.com

+86 755 28459980

Habitación 1510, Edificio 13, Huanancheng, Avenida Ping'an n.° 1, Distrito de Longgang, Shenzhen, Guangdong, China