Our engineers are trained to use cutting-edge techniques to craft tension spring for exceptional performance,durability,reliability,and cost-effectiveness.We also offer a wide range of tension spring sizes,and materials,allowing us to tailor our products to the unique needs of our customers.

Spécifications de l'acier au carbone: MK-65MN-TCS01 、 MK-65MN-TCS02、 MK-65MN-TCS03、 MK-65MN-TCS04、 MK-65MN-TCS05、 MK-65MN-TCS06、 MK-65MN-TCS07、 MK-65MN-TS08、 MK-65MN-TCS09

Spécifications de l'acier inoxydable 304:MK-304SS-TCS01 、MK-304SS-TCS02 、MK-304SS-TCS03 、MK-304SS-TCS04 、MK-304SS-TCS05、MK-304SS-TCS06、MK-304SS-TCS07、MK-304SS-TCS08

Hook-end extension springs are commonly used in various mechanical devices, particularly in scenarios where precise movement control or tension is required.

Hook-end extension springs are used to control the opening and closing of doors or to maintain the tension and position of certain components.

It provides elastic tension, allowing users to stretch and release for exercise or entertainment purposes.

Hook-end extension springs are used to keep doors and windows tightly closed or to control the opening angle. They also provide a gentle closing force to prevent the door from slamming shut.

Used to ensure stability of the equipment during operation or provide the necessary tension.

Nous avons la capacité de fournir à nos clients des ressorts de compression personnalisés pour répondre à presque toutes les spécifications

Your customers demand the highest quality springs for maximum load capacity and at Makeway Spring we have the springs you need. Our commitment to the highest quality spring for your application starts with the spring stock and doesn’t end until we pack and ship the last coil to complete your order.

Essais de matériaux :

We monitor every lot of wire material that is submitted for testing and prototyping to ensure the highest quality product.

Précision dimensionnelle :

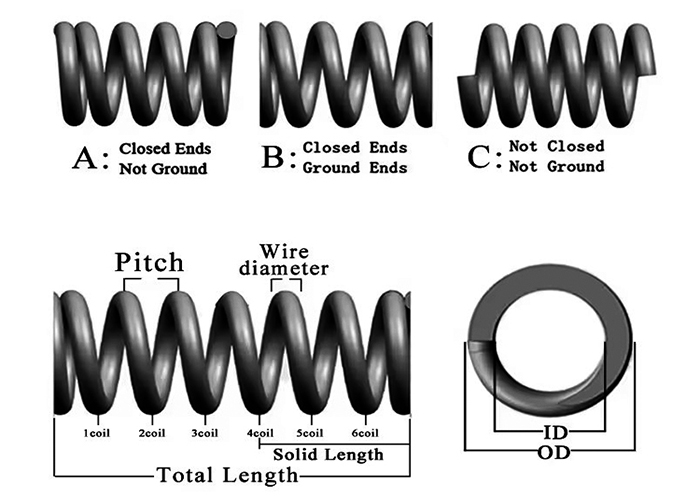

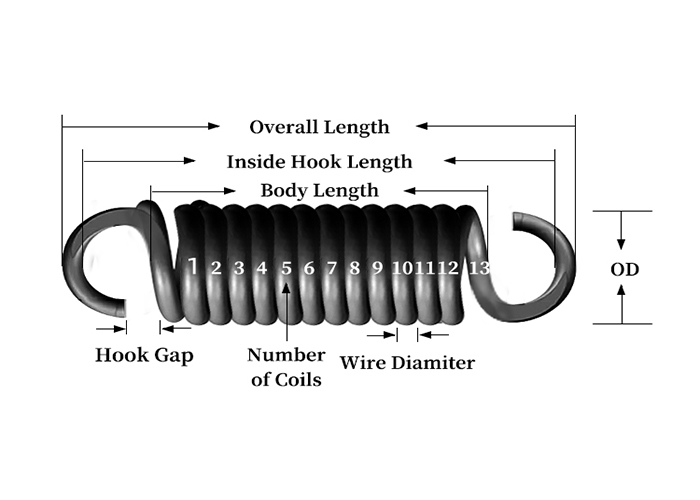

This involves measuring critical dimensions of the extension spring, such as wire diameter, outer diameter, length, and the number of active coils. This ensures that the spring conforms to your specified design requirements.

Test de charge :

This test involves subjecting the extension spring to various loads to verify that it can extend and retract without any deformation or failure. The load should be applied gradually to prevent sudden overloading

Elasticity and Stress Testing:

This test evaluates how well the spring returns to its original shape after being stretched. It measures factors like modulus of elasticity and yield strength to ensure the spring can handle the expected loads.

Fatigue Testing:

Extension springs are often subjected to repeated cycles of loading and unloading. Fatigue testing simulates these conditions to ensure the spring can withstand the anticipated number of cycles without failure

Test de charge :

This involves applying a load to the spring and measuring the corresponding deflection. This helps characterize the spring’s behavior under different loads.

Visual Inspection:

A visual examination of the spring is crucial to identify any surface defects, such as cracks, pitting, or other anomalies.

Tension springs store energy and resist pulling forces by elongating under load and returning to their original length. Typically made of stainless steel for durability and corrosion resistance, they’re vital in mechanical systems.

When selecting an extension spring with hooks, consider the following:

The tension an extension spring can handle depends on its material,wire diameter,number of coils,and design.Different specifications of extension springs are suited for various loads and applications.Manufacturers typically provide the maximum load specifications to ensure safe use.

The lifespan of an extension spring depends on factors such as usage frequency,applied tension,material,and environmental conditions.High-quality materials and proper surface treatments can extend the life of the spring.

Yes,if made from stainless steel or treated for corrosion resistance (e.g.,galvanized or coated),extension springs with hooks are suitable for outdoor or humid environments and can maintain performance for long period

End treatment plays a crucial role in the functionality and durability of extension springs.Common methods include closed and ground ends,open ends with hooks or loops,or other specialized configurations.Proper finishing,such as shot peening or coating,can enhance corrosion resistance and surface quality.

Quality control is paramount in extension spring manufacturing.This includes dimensional inspections,load testing,stress and elasticity testing,material analysis,and visual inspections.Additionally, following relevant industry standards and adhering to specific customer requirements is crucial for producing reliable and consistent springs.

De la conception initiale du ressort à sa fabrication et à sa livraison, nos meilleures pratiques et notre assurance qualité vous garantissent des pièces parfaitement adaptées à votre projet. Chaque solution est conçue pour répondre à vos besoins.

Les ressorts de compression sont un type courant de ressorts conçus pour résister aux forces de compression. Ces ressorts sont généralement spiralés et sont largement utilisés dans des applications telles que les suspensions automobiles, les machines industrielles et les appareils électroniques.

Les ressorts de matrice sont conçus pour les applications à fortes charges et sont couramment utilisés dans les matrices et ensembles d'emboutissage. Ces ressorts sont généralement fabriqués en acier allié haute résistance, offrant une meilleure résistance à la compression et une durée de vie prolongée.

Les ressorts de tension emmagasinent de l'énergie lorsqu'ils sont étirés et reprennent leur forme initiale une fois relâchés. Ils sont couramment utilisés dans des applications telles que les serrures de porte, les jouets et les appareils mécaniques. Ils sont généralement dotés de crochets de fixation à chaque extrémité.

Les ressorts de traction sans tête sont similaires aux ressorts de traction classiques, mais dépourvus de crochets ou d'extrémités traditionnels. Ces ressorts sont utilisés dans les applications nécessitant des méthodes de fixation spécifiques pour répondre aux exigences de conception.

Les ressorts d'horloge, aussi appelés ressorts moteurs, sont des ressorts hélicoïdaux utilisés pour stocker l'énergie mécanique. Ils sont largement utilisés dans les horloges, les jouets et autres appareils nécessitant un stockage d'énergie. Ces ressorts peuvent être remontés manuellement ou mécaniquement, puis libèrent de l'énergie pour alimenter des dispositifs mécaniques.

Les ressorts de torsion sont conçus pour résister à un couple ou à une force de rotation. Ils sont couramment utilisés dans les pinces, les interrupteurs, les portes de garage et autres dispositifs soumis à une force de rotation, créant ainsi une force de contre-rotation.

Les ressorts en laiton sont fabriqués à partir de laiton, un matériau offrant une excellente résistance à la corrosion et une excellente conductivité électrique. Ils sont souvent utilisés dans les applications nécessitant une résistance à la corrosion ou une conductivité électrique, comme les interrupteurs et les bornes électriques.

Le formage de fils comprend divers ressorts et pièces formés par pliage de fils métalliques. Ces pièces sont conçues sur mesure pour des applications spécifiques et peuvent être réalisées dans des formes complexes adaptées à des dispositifs mécaniques ou électroniques spécifiques.

Obtenez des devis et des informations sur les produits de première main ; nous sommes disponibles 24h/24 et 7j/7 pour vous aider à répondre à toutes vos questions.

info@makeway-llc.com

+86 755 28459980

Salle 1510, bâtiment 13 Huanancheng, 1 avenue Ping'an, district de Longgang, Shenzhen, Guangdong, Chine