At Makeway Spring,we specialize in creating high-quality,custom wire-formed products designed to meet the exact specifications of your project.Whether it’s springs, hooks,or complex wire shapes,we deliver precision-engineered solutions with superior craftsmanship,tailored to a wide range of industries.Contact us today to bring your designs to life!

Spécifications de l'acier inoxydable 304: MK-304SS-WFS01、MK-304SS-WFS02、MK-304SS-WFS03、MK-304SS-WFS04、MK-304SS-WFS05、MK-304SS-WFS06、MK-304SS-WFS07、MK-304SS-WFS08

Wire forms are used for components like suspension springs,seat frames,and clips.

Lightweight and durable wire forms are utilized in aircraft components such as fasteners and brackets.

Wire shelving,hooks and handles are commonly produced for household goods and appliances.

Wire forms act as connectors,springs,and clips in various electronic devices.

Used for mechanical springs,clips,and fasteners in manufacturing and assembly equipment.

We have the capability to provide our customers with custom wire forming to meet nearly any specification

Are you looking for high-performance,precise,and reliable Wire Forming products?Whether it’s for the automotive,electronics,or appliance industries,we offer customized Wire Forming solutions tailored to meet your stringent demands for quality,strength,and durability!

Contact us today to learn more about our Wire Forming solutions!Let us be your reliable partner in driving product innovation and success.

Through rigorous testing and quality control,we are confident in the quality of our Wire Forming products.We are committed to providing customers with high-quality,durable,and high-performance Wire Forming products,ensuring stable and reliable operation in various complex environments.

If you are interested in our Wire Forming products or have any inquiries,please feel free to contact us.We are dedicated to serving you!

Material Quality Testing:

The performance of Wire Forming products is determined by the properties of the metal wire.We conduct material composition analysis and mechanical property testing to ensure compliance with industry standards,providing excellent strength,ductility,and corrosion resistance.

Surface Quality Inspection:

urface finish and flawlessness are important characteristics of high-quality Wire Forming products. We inspect the surface for cracks,dents,or other defects to ensure the product meets stringent appearance and performance standards.

Fatigue Strength Testing:

Wire Forming products often undergo repeated mechanical stress.We simulate stress cycles under real-world conditions to evaluate the fatigue life of the product,ensuring stable performance over long-term use.

Corrosion Resistance Testing:

For products that may be used in corrosive environments,we conduct salt spray tests or other corrosion resistance tests to verify the product’s ability to withstand harsh conditions.

Looking for high-quality wire-formed parts tailored to your exact needs?At Makeway Spring,we specialize in custom wire forming solutions designed to meet the unique demands of your project.Whether it’s precision-engineered springs, clips,hooks,or complex wire shapes,we bring your vision to life with unmatched craftsmanship and precision.

Share your specific requirements with us,and we’ll provide a custom solution tailored to your needs.Whether it’s a small batch or large-scale production,we are here to ensure the success of your project!

At Makeway Spring,we know you may have questions about custom wire forming.Below are answers to some of the most frequently asked questions,helping you understand how our services can meet your project needs.

Wire forming is the process of shaping metal wires through bending,cutting, compression,and other techniques to create various forms.These custom shapes are used in many applications,such as springs,brackets,clamps,connectors,and more.

Material selection depends on the application:

Tolerances depend on the wire diameter and specific shape.Generally,larger wire diameters allow for larger tolerances,while smaller wires require higher precision.CNC-controlled machines usually offer very high accuracy.

Wire diameters typically range from 0.1mm to 20mm,but this depends on the machine's capability and the application requirements.

Yes,using appropriate materials such as high-carbon steel,alloy steel,or stainless steel,combined with the correct heat treatment,high-strength,fatigue-resistant parts can be manufactured for demanding applications.

Some basic shapes (such as U-shapes, helical shapes) are standardized in the industry,but the advantage of wire forming is its flexibility,allowing customers to design different shapes and sizes based on specific needs.

Lead times depend on the complexity of the part,production volume,and whether custom tooling is needed.Typical production times range from a few days to several weeks for regular orders.

De la conception initiale du ressort à sa fabrication et à sa livraison, nos meilleures pratiques et notre assurance qualité vous garantissent des pièces parfaitement adaptées à votre projet. Chaque solution est conçue pour répondre à vos besoins.

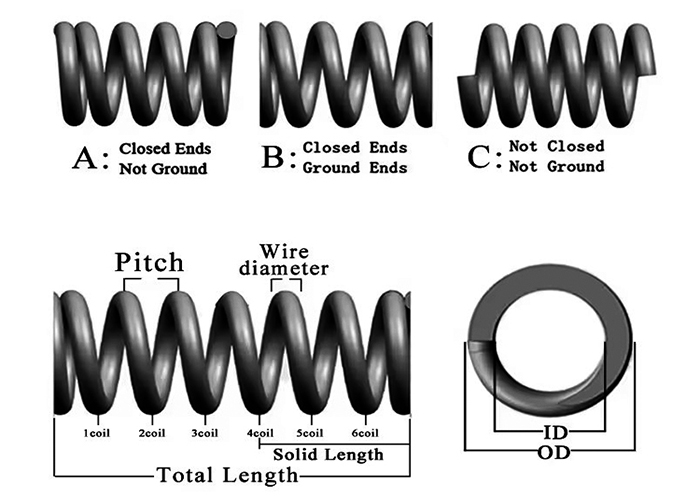

Les ressorts de compression sont un type courant de ressorts conçus pour résister aux forces de compression. Ces ressorts sont généralement spiralés et sont largement utilisés dans des applications telles que les suspensions automobiles, les machines industrielles et les appareils électroniques.

Les ressorts de matrice sont conçus pour les applications à fortes charges et sont couramment utilisés dans les matrices et ensembles d'emboutissage. Ces ressorts sont généralement fabriqués en acier allié haute résistance, offrant une meilleure résistance à la compression et une durée de vie prolongée.

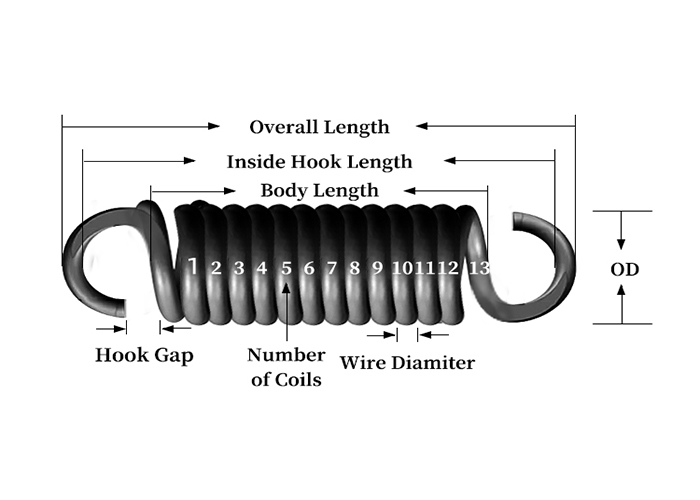

Les ressorts de tension emmagasinent de l'énergie lorsqu'ils sont étirés et reprennent leur forme initiale une fois relâchés. Ils sont couramment utilisés dans des applications telles que les serrures de porte, les jouets et les appareils mécaniques. Ils sont généralement dotés de crochets de fixation à chaque extrémité.

Les ressorts de traction sans tête sont similaires aux ressorts de traction classiques, mais dépourvus de crochets ou d'extrémités traditionnels. Ces ressorts sont utilisés dans les applications nécessitant des méthodes de fixation spécifiques pour répondre aux exigences de conception.

Les ressorts d'horloge, aussi appelés ressorts moteurs, sont des ressorts hélicoïdaux utilisés pour stocker l'énergie mécanique. Ils sont largement utilisés dans les horloges, les jouets et autres appareils nécessitant un stockage d'énergie. Ces ressorts peuvent être remontés manuellement ou mécaniquement, puis libèrent de l'énergie pour alimenter des dispositifs mécaniques.

Les ressorts de torsion sont conçus pour résister à un couple ou à une force de rotation. Ils sont couramment utilisés dans les pinces, les interrupteurs, les portes de garage et autres dispositifs soumis à une force de rotation, créant ainsi une force de contre-rotation.

Les ressorts en laiton sont fabriqués à partir de laiton, un matériau offrant une excellente résistance à la corrosion et une excellente conductivité électrique. Ils sont souvent utilisés dans les applications nécessitant une résistance à la corrosion ou une conductivité électrique, comme les interrupteurs et les bornes électriques.

Wire forms include various springs and parts formed by bending metal wire into shapes. These are custom-designed for specific applications and can be made into complex shapes to fit unique mechanical or electronic devices.

Obtenez des devis et des informations sur les produits de première main ; nous sommes disponibles 24h/24 et 7j/7 pour vous aider à répondre à toutes vos questions.

info@makeway-llc.com

+86 755 28459980

Salle 1510, bâtiment 13 Huanancheng, 1 avenue Ping'an, district de Longgang, Shenzhen, Guangdong, Chine