At Makeway Spring, we have experience with all types of die springs. All our springs are built to the highest standards to operate above industry standards and are used in machinery including farm machinery and 3D printing.

Specifiche dell'acciaio al carbonio: MK-65MN-DS01 、MK-65MN-DS02、MK-65MN-DS03、MK-65MN-DS04、MK-65MN-DS05

Alloy Specifications: MK-AS-DS01 、MK-AS-DS02、MK-AS-DS03、MK-AS-DS04、MK-AS-DS05

Factors that are important while choosing which die spring is best for your project:

By purchasing through Makeway Spring you will have the best product for various applications.Contact us at any time and one of our customer service team members can help you out with your custom order or request an estimate below.

Abbiamo la capacità di fornire ai nostri clienti molle di compressione personalizzate per soddisfare quasi tutte le specifiche

In the world of heavy machinery and industrial applications,precision is paramount.At Makeway Spring,our die springs undergo rigorous testing to guarantee impeccable performance.

In the world of heavy machinery and industrial applications,precision is paramount.At Makeway Spring,our die springs undergo rigorous testing to guarantee impeccable performance.

Load Testing:

This test involves subjecting the die spring to different loads to verify that it can compress and return to its original position without deformation or failure. It ensures that the spring can handle the expected loads in the application.

Deflection Testing:

This test measures the spring’s deflection under a specified load. It helps determine the spring’s behavior when subjected to a particular force and ensures it meets the design requirements.

Stress and Strain Testing:

This involves evaluating the spring’s response to applied stress. It helps determine the spring’s elastic and plastic deformation behavior and ensures it can handle the expected working conditions.

Analisi dei materiali:

Testing the material properties of the spring, including tensile strength, yield strength, and composition, ensures it meets the specified standards for the application.

Die Spring design is not always one-size-fits-all. We at Makeway Spring pride ourselves on having the best engineers and top-notch customer service. No other manufacturer will offer you better service and when you need custom springs made, our team is clutch. We work hard so you can be sure your custom heavy duty metal Die springs.

ie springs,built for heavy machinery,use high-quality alloyed steel for superior load-bearing.Essential for industrial machines,proper selection and maintenance are key for longevity.They come in various configurations to suit different needs.

Die springs are heavy-duty compression springs that are commonly used in die machinery,stamping presses, and other heavy-duty industrial applications.They are designed to withstand high load and provide reliable and consistent performance.

Die springs offer several benefits,including high load-bearing capacity,long service life,efficient energy absorption,and resistance to fatigue and wear.They provide consistent force throughout their working range and are available in various sizes and force ratings to meet specific application requirements.

When selecting a die spring,you need to consider factors such as the required load capacity,working environment conditions, spring size and type,and the desired deflection and force specifications.It is recommended to consult with a spring manufacturer or engineer to ensure you choose the right spring for your application.

Die springs are often color-coded to distinguish between different force ratings.The commonly used color codes are lightest load (blue), light load (yellow),medium load (red), heavy load (green),extra-heavy load (brown), and ultra-heavy load (purple).

Yes, die springs can be customized to meet specific load capacities,sizes,and force specifications.Customization options include altering the outer diameter,inner diameter,wire size,and length to suit your application needs.

The lifespan of die springs depends on several factors,such as the application’s operating conditions,load profile,and proper maintenance.However, die springs are designed to have a long service life and can withstand millions of cycles under normal operating conditions.

Die springs are primarily designed for heavy-duty industrial applications.While they may be used in some non-industrial applications,it is recommended to consult with a spring manufacturer or engineer to determine the suitability of die springs for your specific application.

Yes,Makeway Spring can handle orders of all sizes,from small to large.Whether you need a single die spring or a large quantity for your production line,we can provide customized solutions to meet your specific needs.

Dalla progettazione iniziale della molla alla produzione e alla consegna, le nostre best practice e il nostro controllo qualità garantiscono la consegna di componenti precisi e realizzati appositamente per il tuo progetto. Ogni soluzione è progettata per le tue esigenze.

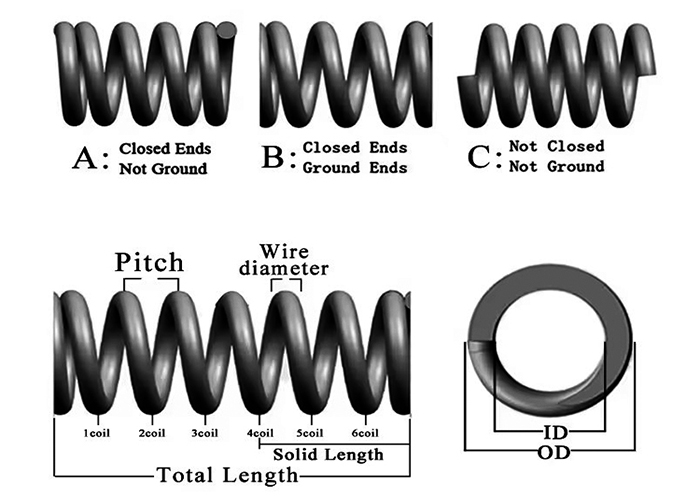

Le molle a compressione sono un tipo comune di molla progettata per resistere alle forze di compressione. Queste molle sono tipicamente avvolte e sono ampiamente utilizzate in applicazioni come sospensioni automobilistiche, macchinari industriali e dispositivi elettronici.

Le molle per stampi sono progettate per applicazioni ad alto carico e sono comunemente utilizzate negli stampi per stampaggio e nei set di stampi. Queste molle sono solitamente realizzate in acciaio legato ad alta resistenza, che offre una maggiore resistenza alla compressione e una maggiore durata.

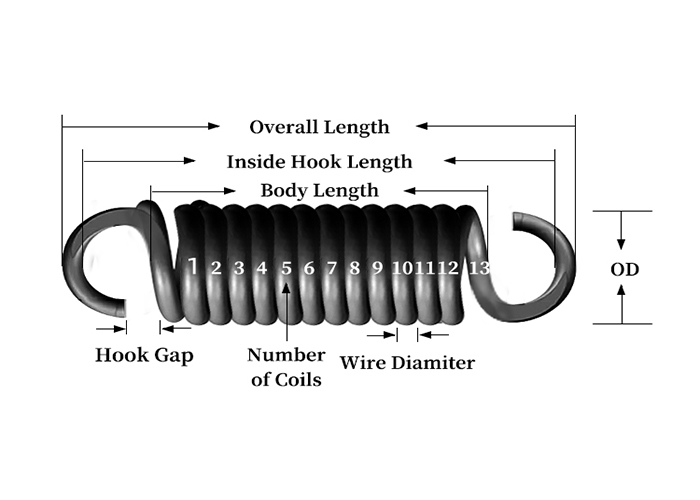

Le molle di trazione immagazzinano energia quando vengono allungate e tornano alla loro forma originale quando vengono rilasciate. Sono comunemente utilizzate in applicazioni come serrature, giocattoli e dispositivi meccanici. Le molle di trazione in genere presentano ganci su entrambe le estremità per il fissaggio.

Le molle di trazione senza testa sono simili alle molle di trazione tradizionali, ma sono prive di ganci o estremità tradizionali. Queste molle vengono utilizzate in applicazioni che richiedono metodi di fissaggio specifici per soddisfare i requisiti di progettazione.

Le molle degli orologi, note anche come molle principali, sono molle a spirale utilizzate per accumulare energia meccanica. Sono ampiamente utilizzate in orologi, giocattoli e altri dispositivi che richiedono un accumulo di energia. Queste molle possono essere caricate manualmente o meccanicamente e quindi rilasciare energia per alimentare dispositivi meccanici.

Le molle di torsione sono progettate per resistere alla coppia o alla forza rotazionale. Queste molle sono comunemente utilizzate in clip, interruttori, porte da garage e altri dispositivi in cui viene applicata una forza rotazionale, fornendo una forza di contrasto tramite torsione.

Le molle in ottone sono realizzate in ottone, materiale che offre un'eccellente resistenza alla corrosione e conduttività elettrica. Sono spesso utilizzate in applicazioni che richiedono resistenza alla corrosione o conduttività elettrica, come interruttori e terminali elettrici.

La formatura del filo comprende varie molle e parti realizzate piegando il filo metallico in forme specifiche. Sono progettate su misura per applicazioni specifiche e possono essere realizzate in forme complesse per adattarsi a dispositivi meccanici o elettronici specifici.

Ottieni preventivi e informazioni sui prodotti di prima mano: siamo disponibili 24 ore su 24, 7 giorni su 7 per rispondere a qualsiasi tua richiesta.

info@makeway-llc.com

+86 755 28459980

Stanza 1510, Edificio 13 Huanancheng, n. 1 Ping'an Avenue, distretto di Longgang, Shenzhen, Guangdong, Cina