At Makeway Spring,we specialize in creating high-quality,custom wire-formed products designed to meet the exact specifications of your project.Whether it’s springs, hooks,or complex wire shapes,we deliver precision-engineered solutions with superior craftsmanship,tailored to a wide range of industries.Contact us today to bring your designs to life!

304ステンレス鋼の仕様: MK-304SS-WFS01、MK-304SS-WFS02、MK-304SS-WFS03、MK-304SS-WFS04、MK-304SS-WFS05、MK-304SS-WFS06、MK-304SS-WFS07、MK-304SS-WFS08

Wire forms are used for components like suspension springs,seat frames,and clips.

Lightweight and durable wire forms are utilized in aircraft components such as fasteners and brackets.

Wire shelving,hooks and handles are commonly produced for household goods and appliances.

Wire forms act as connectors,springs,and clips in various electronic devices.

Used for mechanical springs,clips,and fasteners in manufacturing and assembly equipment.

We have the capability to provide our customers with custom wire forming to meet nearly any specification

Are you looking for high-performance,precise,and reliable Wire Forming products?Whether it’s for the automotive,electronics,or appliance industries,we offer customized Wire Forming solutions tailored to meet your stringent demands for quality,strength,and durability!

Contact us today to learn more about our Wire Forming solutions!Let us be your reliable partner in driving product innovation and success.

Through rigorous testing and quality control,we are confident in the quality of our Wire Forming products.We are committed to providing customers with high-quality,durable,and high-performance Wire Forming products,ensuring stable and reliable operation in various complex environments.

If you are interested in our Wire Forming products or have any inquiries,please feel free to contact us.We are dedicated to serving you!

Material Quality Testing:

The performance of Wire Forming products is determined by the properties of the metal wire.We conduct material composition analysis and mechanical property testing to ensure compliance with industry standards,providing excellent strength,ductility,and corrosion resistance.

Surface Quality Inspection:

urface finish and flawlessness are important characteristics of high-quality Wire Forming products. We inspect the surface for cracks,dents,or other defects to ensure the product meets stringent appearance and performance standards.

Fatigue Strength Testing:

Wire Forming products often undergo repeated mechanical stress.We simulate stress cycles under real-world conditions to evaluate the fatigue life of the product,ensuring stable performance over long-term use.

Corrosion Resistance Testing:

For products that may be used in corrosive environments,we conduct salt spray tests or other corrosion resistance tests to verify the product’s ability to withstand harsh conditions.

Looking for high-quality wire-formed parts tailored to your exact needs?At Makeway Spring,we specialize in custom wire forming solutions designed to meet the unique demands of your project.Whether it’s precision-engineered springs, clips,hooks,or complex wire shapes,we bring your vision to life with unmatched craftsmanship and precision.

Share your specific requirements with us,and we’ll provide a custom solution tailored to your needs.Whether it’s a small batch or large-scale production,we are here to ensure the success of your project!

At Makeway Spring,we know you may have questions about custom wire forming.Below are answers to some of the most frequently asked questions,helping you understand how our services can meet your project needs.

Wire forming is the process of shaping metal wires through bending,cutting, compression,and other techniques to create various forms.These custom shapes are used in many applications,such as springs,brackets,clamps,connectors,and more.

Material selection depends on the application:

Tolerances depend on the wire diameter and specific shape.Generally,larger wire diameters allow for larger tolerances,while smaller wires require higher precision.CNC-controlled machines usually offer very high accuracy.

Wire diameters typically range from 0.1mm to 20mm,but this depends on the machine's capability and the application requirements.

Yes,using appropriate materials such as high-carbon steel,alloy steel,or stainless steel,combined with the correct heat treatment,high-strength,fatigue-resistant parts can be manufactured for demanding applications.

Some basic shapes (such as U-shapes, helical shapes) are standardized in the industry,but the advantage of wire forming is its flexibility,allowing customers to design different shapes and sizes based on specific needs.

Lead times depend on the complexity of the part,production volume,and whether custom tooling is needed.Typical production times range from a few days to several weeks for regular orders.

スプリングの初期設計から製造、納品まで、当社のベストプラクティスと品質保証により、お客様のプロジェクトに最適な精密な部品をお届けします。あらゆるソリューションはお客様のニーズに合わせて設計されています。

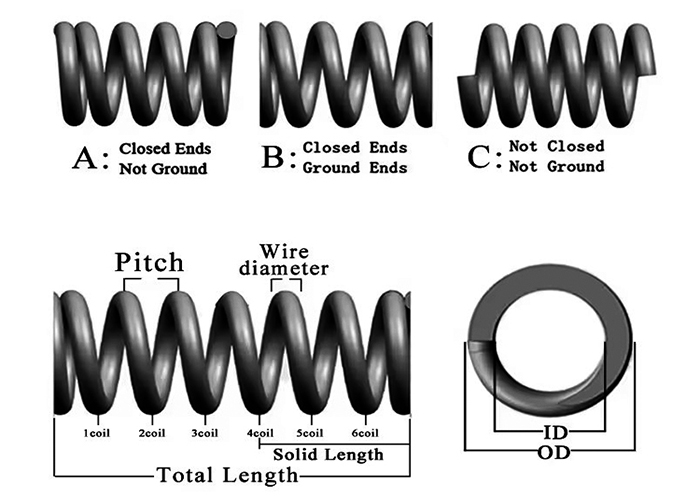

圧縮ばねは、圧縮力に抵抗するように設計された一般的なばねの一種です。これらのばねは通常コイル状に巻かれており、自動車のサスペンション、産業機械、電子機器などの用途で広く使用されています。

ダイスプリングは高荷重用途向けに設計されており、プレス金型やダイセットによく使用されます。これらのスプリングは通常、高強度合金鋼で作られており、圧縮耐性が高く、長寿命です。

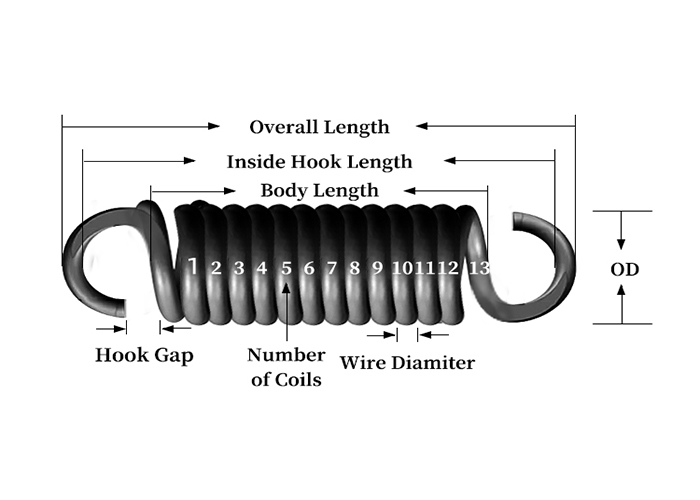

テンションスプリングは、伸ばされるとエネルギーを蓄え、放すと元の形状に戻ります。ドアロック、玩具、機械装置などの用途に広く使用されています。テンションスプリングは通常、両端に取り付け用のフックが付いています。

ヘッドレステンションスプリングは通常のテンションスプリングに似ていますが、従来のフックや端部がありません。これらのスプリングは、設計要件を満たすために特別な取り付け方法が必要な用途で使用されます。

時計用ゼンマイ(ゼンマイとも呼ばれる)は、機械エネルギーを蓄えるために使用されるコイル状のバネです。時計、玩具、その他エネルギー貯蔵を必要とする機器に広く使用されています。これらのゼンマイは、手巻きまたは機械巻きで巻き上げられ、エネルギーを放出することで機械装置に動力を与えます。

ねじりばねは、トルクまたは回転力に耐えるように設計されています。これらのばねは、クリップ、スイッチ、ガレージドアなど、回転力が加わるその他の装置によく使用され、ねじりによって反作用力を提供します。

真鍮スプリングは真鍮素材で作られており、優れた耐食性と導電性を備えています。電気スイッチや端子など、耐食性や導電性が求められる用途によく使用されます。

Wire forms include various springs and parts formed by bending metal wire into shapes. These are custom-designed for specific applications and can be made into complex shapes to fit unique mechanical or electronic devices.

直接の見積もりと製品情報を入手してください。お問い合わせには 24 時間 365 日対応いたします。

info@makeway-llc.com

+86 755 28459980

中国広東省深圳市龍崗区平安大道1号華南城ビル13号1510号室