第25回広州国際春物産業博覧会が盛況のうちに終了

The 25th Guangzhou International Spring Industry Exhibition Successfully Concluded In May 2025, the 25th Guangzhou International Spring Industry Exhibition came to a successful close at the Pazhou Exhibition Center. MAKEWAY participated actively in the event, showcasing a wide range of high-quality spring products that attracted significant attention from both domestic and international visitors. During the exhibition, the MAKEWAY team engaged in face-to-face discussions with a large number of attendees, introducing our advanced spring manufacturing capabilities and technical strengths. Our featured products—including compression springs, extension springs, and torsion springs—were well received by industry professionals. The event was a great success not only in strengthening relationships with existing partners but also in establishing valuable connections with new customers. Many of these new contacts expressed strong interest in our products, highlighting their high quality, durability, and innovative design. Visitors acknowledged that MAKEWAY’s springs are ideal for applications across various industries, particularly in automation equipment, precision instruments, and consumer electronics, where reliability and performance are crucial. We sincerely thank all customers, partners, and friends who visited our booth. Moving forward, MAKEWAY will continue to innovate and deliver even better spring solutions to meet the evolving needs of global industries. For more information about our products and updates, please visit our official website: https://makeway-llc.com/

産業機械における圧縮ばねの代表的な応用例

5 Typical Applications of Compression Springs in Industrial Machinery 5 Typical Applications of Compression Springs in Industrial Machinery 1. Shock Absorption Systems Compression springs are widely used in shock absorption systems to cushion impacts and reduce vibrations. This is crucial in heavy machinery, vehicles, and even construction equipment. Authoritative Reference: Engineering Toolbox – Spring Calculations 2. Valve Mechanisms In many industrial machines, valves require precise opening and closing mechanisms. Compression springs ensure that valves operate smoothly and maintain optimal pressure during operation. Learn more about our Valve Control Systems. Authoritative Reference: Valve Magazine – Springs in Valve Applications 3. Industrial Presses Compression springs are an integral part of industrial presses, where they assist in maintaining consistent pressure and support during stamping and molding processes. Explore our high-performance Industrial Press Solutions. Authoritative Reference: Springer – Advanced Manufacturing Technology 4. Load Balancing Systems In load-balancing applications, compression springs are used to distribute weight evenly across mechanical structures. This prevents strain and extends the lifespan of equipment. Visit our Load Balancing Solutions for more information. Authoritative Reference: Machine Design – Fundamentals of Spring Design 5. Suspension Systems One of the most common applications of compression springs is in suspension systems. They help absorb shocks from uneven terrain and provide stability to vehicles and industrial platforms. Learn more about our Suspension Solutions. Authoritative Reference: SAE International – Suspension System Design Conclusion Compression springs are vital in a range of industrial applications, offering stability, precision, and durability. At Makeway LLC, we specialize in providing top-quality industrial spring solutions tailored to your needs. Visit our Product Page to explore more.

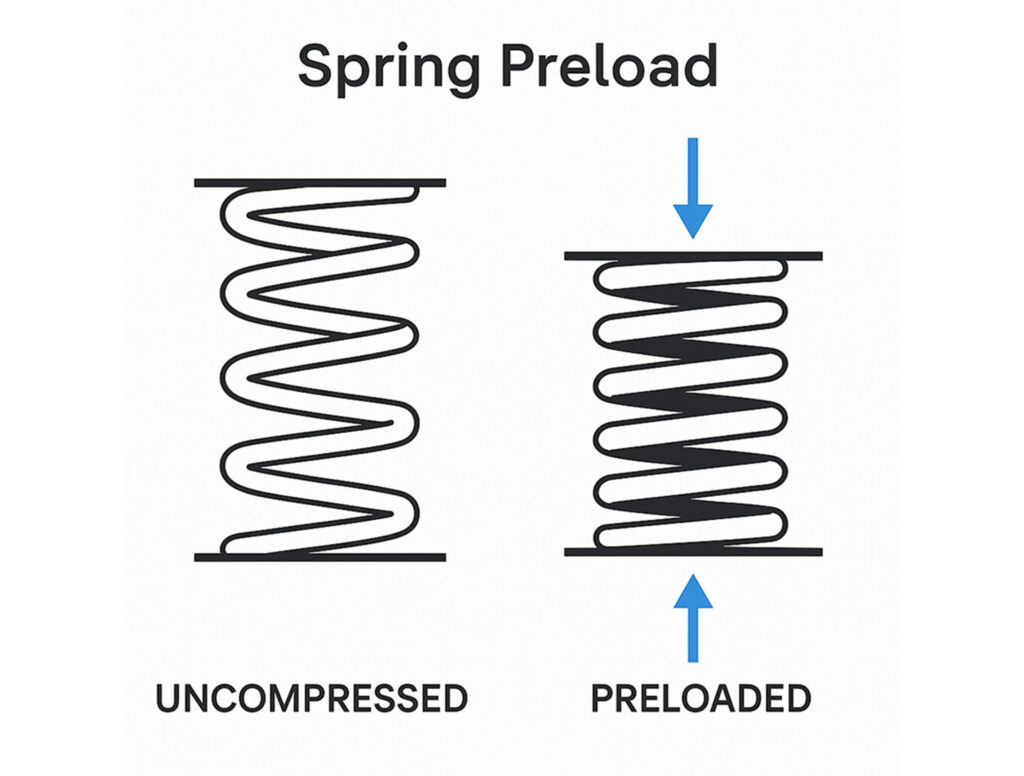

工業用ばねにおける予圧縮設計の原理分析

Introduction In industrial mechanical design, springs are fundamental components widely used in damping, energy storage, buffering, and more. Preload, as a critical design strategy, significantly improves spring performance and reliability. So, what is preload? How does it affect the practical application of industrial springs? This article provides a detailed analysis of preload design principles and its essential role in mechanical applications. What is Spring Preload? Spring preload refers to the initial force or displacement applied to a spring before it enters its working state. In other words, preload is a “pre-activation” design that places the spring in a certain stress state before any external load is applied. This minimizes the spring’s non-linear range, making its operation more stable and predictable. The Role of Spring Preload in Mechanical Applications Elimination of Free Play: For high-precision equipment, preload can eliminate free play, ensuring immediate mechanical response. Improved Response Speed: Since the spring is already under tension, it quickly enters a loaded state, reducing lag time. Reduced Vibration and Shock: Preload reduces displacement jumps during sudden loading, resulting in smoother operation. Enhanced Fatigue Life: Preloading avoids abrupt large displacements, reducing material fatigue accumulation. Preload Design Principles in Industrial Springs How Preload Enhances Spring Performance: Preloading allows the spring to enter a partially deformed state before loading, minimizing the reaction time during operation. Impact of Preload on Fatigue Life: Industrial springs under cyclic loading may experience fatigue damage. Preload reduces strain amplitude, significantly extending service life. Design Considerations: Preload design must consider working load, spring material properties, and environmental conditions. Excessive preload may lead to spring yield or premature failure. [Insert Real Application Scene Images here] Real-world Applications Positioning systems in precision instruments Shock absorbers in hydraulic equipment Stabilization devices in automotive suspension systems Conclusion Preload, as a design strategy, effectively optimizes the response speed, stability, and durability of industrial springs. For high-precision machinery and long-term load environments, proper preload design is key to enhancing performance and extending lifespan. As industrial technology advances, preload will continue to play a vital role in promoting stability and reliability in mechanical design. References Makeway LLC Official Website Springer – Authoritative Books and Research on Spring Design Engineering Toolbox – Engineering Tools and Design Calculations

第25回広州国際スプリング産業展示会でMAKEWAYにお越しください

Visit MAKEWAY at the 25th Guangzhou International Spring Industry Exhibition MAKEWAY Spring Company is honored to announce our participation in the 25th Guangzhou International Spring Industry Exhibition. This exhibition is one of the most important events in the spring manufacturing industry. It brings together leaders, manufacturers, and professionals from around the world. Therefore, it presents an excellent opportunity for you to explore new spring technologies and innovative solutions. We encourage you to visit our booth to see firsthand how MAKEWAY is leading the way in spring manufacturing. Event Details: Date: May 10-12, 2025 Location: China Import and Export Fair Complex, Area C, 980 Xingang East Road, Haizhu District, Guangzhou, China Why Should You Visit MAKEWAY at the Exhibition? MAKEWAY specializes in precision-engineered springs. Whether you require compression springs, torsion springs, or tension springs, our products are designed to meet the highest quality standards. Here’s why you should visit us: Explore Our Product Range: Learn about our compression springs, torsion springs, and tension springs, all tailored to various applications. Experience Live Demonstrations: Watch how we manufacture and test our springs in real-time. Meet Our Experts: Our engineering team will be on hand to discuss your specific needs and offer custom solutions. Discover New Innovations: Stay ahead of the curve by learning about the latest developments in spring technology. Expand Your Network: Connect with industry peers, suppliers, and potential business partners. Our Products at the Exhibition MAKEWAY is renowned for our high-quality springs. Our precise manufacturing processes guarantee durability, performance, and reliability. Let us take a moment to highlight some of our featured products: Compression Springs Compression springs are ideal for applications that require high load resistance. Available in various materials, including stainless steel, carbon steel, and alloy steel, these springs can withstand significant compressive forces without losing their shape or strength. Torsion Springs Torsion springs work by storing energy through twisting. These springs are perfect for applications involving rotational movement, such as garage doors or automotive parts. We ensure that all torsion springs are manufactured to precise specifications for peak performance. Tension Springs Tension springs resist stretching forces and are commonly used in pull-back mechanisms, automotive components, and industrial machinery. We provide a wide range of sizes and materials to meet your specific requirements. Network and Gain Industry Insights The exhibition is the perfect place to discover the latest trends, technologies, and innovations in spring manufacturing. Moreover, it offers a valuable opportunity to connect with leaders in the industry, share ideas, and discuss future projects. By attending, you will see firsthand how MAKEWAY is driving innovation in spring manufacturing. If you are interested in meeting our team or scheduling a one-on-one discussion, please contact us today. We are eager to meet you at the exhibition! Don’t miss this chance to visit MAKEWAY at the Guangzhou Spring Exhibition! For more details, visit the official website of the Guangzhou International Spring Industry Exhibition. Visit MAKEWAY at the 25th Guangzhou Spring Exhibition | May 10-12, 2025

バネの作り方:鋼線から精密部品まで

Springs are essential components used in many industries, from industrial machinery to consumer electronics. However, the process of making these springs involves several steps, and each step is crucial to ensuring the final product’s quality. The journey begins with the selection of the right material. Steel wire, which is often chosen for its strength and flexibility, is carefully selected. This material will eventually be shaped into compression, torsion, or tension springs, depending on the application. Learn more about compression springs here. Choosing the right spring material: High Carbon Steel, Alloy Steel, or Stainless Steel 1. Choosing the Right Material: The Foundation of a Spring The selection of the right material is one of the most important steps. High-carbon steel, alloy steel, and stainless steel are commonly used. Each material has its unique properties, which will affect the spring’s strength, corrosion resistance, and elasticity. For example, high-carbon steel is often selected for general-purpose springs due to its durability. Stainless steel, on the other hand, is preferred when resistance to corrosion is required. These materials are thoroughly tested before they are used in the manufacturing process. Cold and Hot Drawing: Steel wire transformation in spring manufacturing 2. Drawing the Steel Wire: Cold and Hot Drawing Methods Once the material is selected, the wire is drawn into shape. This process can either be done cold or hot, depending on the wire’s intended use. Cold drawing is typically used for smaller diameter wires, as it enhances the material’s strength. In contrast, hot drawing is used for larger diameter wires and allows for easier shaping. Both methods result in wire that is ready for coiling into the desired spring form. Spring Coiling: The process of turning wire into functional spring shapes 3. Forming the Spring: Coiling or Bending After the wire has been drawn, it is then coiled into the desired shape. The wire can be coiled into several types of springs, including compression, torsion, and tension springs. For compression springs, the wire is wound into a helix. This process is performed on a compression spring machine. Torsion springs are coiled to resist rotational forces, while tension springs are designed to resist pulling forces. Special machines are used to ensure the springs are accurately coiled. Heat Treatment: The process of strengthening springs through heat 4. Heat Treatment: Strengthening the Spring Heat treatment is used to enhance the mechanical properties of the spring. During this process, the spring is heated to a specific temperature, then cooled rapidly to harden it. Different heat treatments, such as annealing, quenching, and tempering, are employed to adjust the spring’s strength and flexibility. These processes are critical to ensuring the spring performs as expected in its final application. Precision Finishing: Ensuring the perfect dimensions and flatness of the spring ends 5. Precision Finishing: Ensuring Accuracy After heat treatment, the spring undergoes a series of finishing processes. These include cutting, grinding, and polishing. The ends of the spring are ground to ensure they are flat, which is essential for proper installation. These steps ensure that the spring meets the required specifications and can function as intended in various applications. Additionally, each spring is tested for its mechanical properties to ensure its performance. Surface Treatment: Adding coatings to enhance the spring’s durability and corrosion resistance 6. Surface Treatment: Enhancing Durability In certain cases, surface treatments are applied to improve the spring’s durability. This may include electroplating, coating, or other methods. Electroplating involves applying a thin layer of metal, such as zinc or nickel, to protect the spring from corrosion. Coating methods, such as powder coating, are also used to provide additional protection against wear and corrosion. These treatments are especially important for springs used in harsh environments. 7. Quality Control: Ensuring Perfect Performance Finally, the spring undergoes a series of rigorous tests. These tests are conducted to ensure that the spring meets the required specifications for strength, elasticity, and durability. The spring is subjected to various loads and tested for its performance over time. Springs that pass these tests are deemed ready for use in their respective applications. 8. Applications: Where Springs are Used Springs are used in a variety of industries, from automotive to aerospace, electronics, medical devices, and more. Depending on the application, the type of spring and material chosen will vary. Compression springs are often used in mechanical assemblies, while torsion springs and tension springs are used in more specialized equipment. Custom springs are frequently designed to meet specific requirements, ensuring optimal performance in each application. If you are interested in learning more about our custom springs or need assistance selecting the right spring for your application, contact us today. For more information on spring manufacturing and materials, check out the detailed guide from Springer, a leading publisher in mechanical engineering.

ステンレス鋼と炭素鋼の圧縮スプリングの選び方

How to Choose Between Stainless Steel and Carbon Steel Compression Springs When designing high-performance mechanical or electronic systems, the choice of spring material is not just technical—it’s strategic. Stainless steel and carbon steel are two of the most commonly used materials for compression springs, but each offers distinct advantages depending on your specific application. This article compares both materials from multiple angles—corrosion resistance, mechanical properties, lifecycle cost, maintenance, and real-world applications—to help you select the optimal solution for your industrial or electronic product. Comparison of internal structure between stainless steel and carbon steel springs Overview of the Materials Stainless Steel Compression Springs are typically made from grades like 302, 316, or 17-7PH. These alloys are corrosion-resistant and suitable for environments involving moisture, chemicals, or high hygiene requirements. Carbon Steel Compression Springs are often formed from high-carbon materials like music wire or oil-tempered 65Mn. These offer high strength and elasticity but require protective coatings when exposed to humidity or chemicals. Multi-Angle Comparison: Stainless Steel vs Carbon Steel Factor Stainless Steel Carbon Steel Corrosion Resistance Excellent — Ideal for wet or chemical-rich environments Low — Needs plating (zinc, phosphate, epoxy) for protection Elastic Performance Good, with steady performance across moderate loads Superior — High tensile strength and sharp snapback Thermal Resistance Stable up to 250–300°C (higher for some grades) Moderate — Degrades faster at high temperatures Cost & Manufacturing Higher initial material and processing cost Lower cost, easier to form and source in bulk Maintenance Needs Low — Minimal rusting or degradation over time Moderate — Needs protective finish and periodic checks Finish Appearance Smooth, shiny surface; often no additional treatment needed Matte finish; often dark or plated depending on use Visual comparison of stainless and carbon steel compression springs Application-Based Selection Ideal Use Cases for Stainless Steel Springs Outdoor machinery exposed to rain, salt, or UV (e.g., agricultural drones) Medical devices and surgical tools requiring sterilization Food-grade equipment with hygiene and corrosion regulations Electronics used in humid environments (e.g., smart home sensors) Ideal Use Cases for Carbon Steel Springs Enclosed machinery in factories or labs Consumer electronics requiring high elasticity but minimal exposure Automotive interiors or tool components DIY devices or temporary assemblies where cost is a major factor Performance Over Time: Which Lasts Longer? While carbon steel may perform better under initial loads, it tends to corrode faster and lose tension more rapidly if used in damp or corrosive environments. Stainless steel, though more expensive, offers long-term stability and often lowers the total cost of ownership by reducing failures, replacements, and maintenance downtime. Total cost of ownership over 3 years: Stainless Steel vs Carbon Steel Frequently Asked Questions (FAQ) 1. Can carbon steel springs be used outdoors? Technically yes, but they must be coated with a protective finish (zinc, powder coat, epoxy). Without it, carbon steel will rust quickly in outdoor conditions. 2. Is stainless steel always better? Not always. In dry, enclosed environments, carbon steel often outperforms in elasticity and cost efficiency. Stainless shines where corrosion and reliability are key concerns. 3. Which material is more eco-friendly? Stainless steel is 100% recyclable and often has a longer lifespan, reducing waste. Carbon steel is also recyclable but tends to have higher maintenance and replacement cycles. Next Steps: Find the Right Compression Spring Choosing the right spring material goes beyond specs. It’s about understanding your product’s real-world conditions. Explore our compression spring collection to view available options or contact our team for a personalized recommendation. Have questions or want to request a custom spring? Contact us today — our engineers are ready to help.