At Makeway Spring, we have experience with all types of die springs. All our springs are built to the highest standards to operate above industry standards and are used in machinery including farm machinery and 3D printing.

炭素鋼の仕様: MK-65MN-DS01 、MK-65MN-DS02、MK-65MN-DS03、MK-65MN-DS04、MK-65MN-DS05

Alloy Specifications: MK-AS-DS01 、MK-AS-DS02、MK-AS-DS03、MK-AS-DS04、MK-AS-DS05

Factors that are important while choosing which die spring is best for your project:

By purchasing through Makeway Spring you will have the best product for various applications.Contact us at any time and one of our customer service team members can help you out with your custom order or request an estimate below.

当社は、ほぼあらゆる仕様を満たすカスタム圧縮スプリングをお客様に提供することができます。

In the world of heavy machinery and industrial applications,precision is paramount.At Makeway Spring,our die springs undergo rigorous testing to guarantee impeccable performance.

In the world of heavy machinery and industrial applications,precision is paramount.At Makeway Spring,our die springs undergo rigorous testing to guarantee impeccable performance.

負荷テスト:

This test involves subjecting the die spring to different loads to verify that it can compress and return to its original position without deformation or failure. It ensures that the spring can handle the expected loads in the application.

Deflection Testing:

This test measures the spring’s deflection under a specified load. It helps determine the spring’s behavior when subjected to a particular force and ensures it meets the design requirements.

Stress and Strain Testing:

This involves evaluating the spring’s response to applied stress. It helps determine the spring’s elastic and plastic deformation behavior and ensures it can handle the expected working conditions.

Material Analysis:

Testing the material properties of the spring, including tensile strength, yield strength, and composition, ensures it meets the specified standards for the application.

Die Spring design is not always one-size-fits-all. We at Makeway Spring pride ourselves on having the best engineers and top-notch customer service. No other manufacturer will offer you better service and when you need custom springs made, our team is clutch. We work hard so you can be sure your custom heavy duty metal Die springs.

ie springs,built for heavy machinery,use high-quality alloyed steel for superior load-bearing.Essential for industrial machines,proper selection and maintenance are key for longevity.They come in various configurations to suit different needs.

Die springs are heavy-duty compression springs that are commonly used in die machinery,stamping presses, and other heavy-duty industrial applications.They are designed to withstand high load and provide reliable and consistent performance.

Die springs offer several benefits,including high load-bearing capacity,long service life,efficient energy absorption,and resistance to fatigue and wear.They provide consistent force throughout their working range and are available in various sizes and force ratings to meet specific application requirements.

When selecting a die spring,you need to consider factors such as the required load capacity,working environment conditions, spring size and type,and the desired deflection and force specifications.It is recommended to consult with a spring manufacturer or engineer to ensure you choose the right spring for your application.

Die springs are often color-coded to distinguish between different force ratings.The commonly used color codes are lightest load (blue), light load (yellow),medium load (red), heavy load (green),extra-heavy load (brown), and ultra-heavy load (purple).

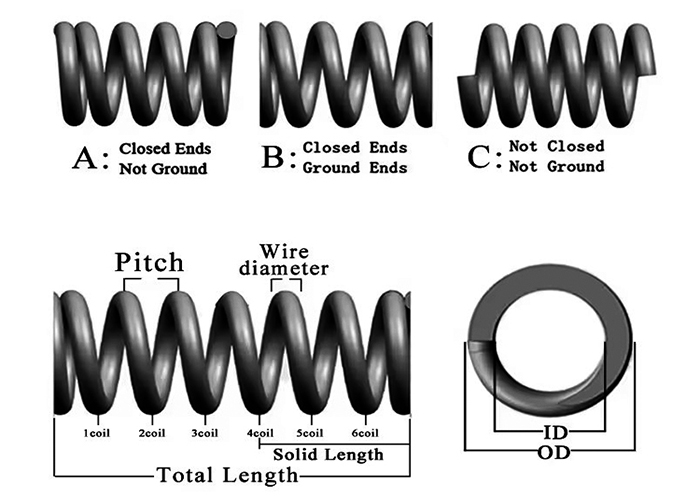

Yes, die springs can be customized to meet specific load capacities,sizes,and force specifications.Customization options include altering the outer diameter,inner diameter,wire size,and length to suit your application needs.

The lifespan of die springs depends on several factors,such as the application’s operating conditions,load profile,and proper maintenance.However, die springs are designed to have a long service life and can withstand millions of cycles under normal operating conditions.

Die springs are primarily designed for heavy-duty industrial applications.While they may be used in some non-industrial applications,it is recommended to consult with a spring manufacturer or engineer to determine the suitability of die springs for your specific application.

Yes,Makeway Spring can handle orders of all sizes,from small to large.Whether you need a single die spring or a large quantity for your production line,we can provide customized solutions to meet your specific needs.

スプリングの初期設計から製造、納品まで、当社のベストプラクティスと品質保証により、お客様のプロジェクトに最適な精密な部品をお届けします。あらゆるソリューションはお客様のニーズに合わせて設計されています。

圧縮ばねは、圧縮力に抵抗するように設計された一般的なばねの一種です。これらのばねは通常コイル状に巻かれており、自動車のサスペンション、産業機械、電子機器などの用途で広く使用されています。

ダイスプリングは高荷重用途向けに設計されており、プレス金型やダイセットによく使用されます。これらのスプリングは通常、高強度合金鋼で作られており、圧縮耐性が高く、長寿命です。

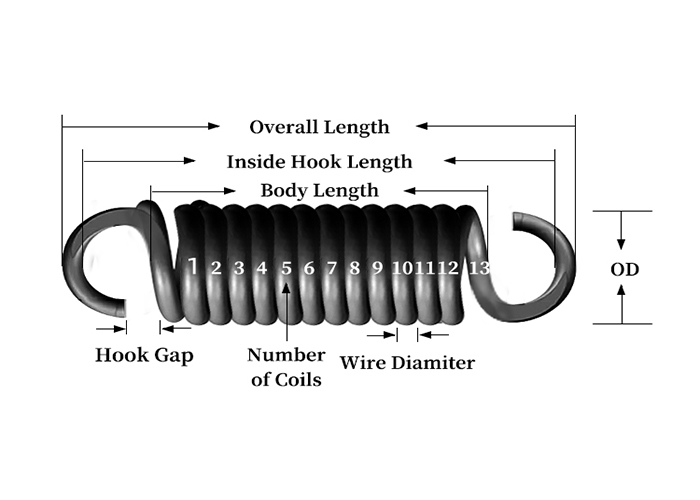

テンションスプリングは、伸ばされるとエネルギーを蓄え、放すと元の形状に戻ります。ドアロック、玩具、機械装置などの用途に広く使用されています。テンションスプリングは通常、両端に取り付け用のフックが付いています。

ヘッドレステンションスプリングは通常のテンションスプリングに似ていますが、従来のフックや端部がありません。これらのスプリングは、設計要件を満たすために特別な取り付け方法が必要な用途で使用されます。

時計用ゼンマイ(ゼンマイとも呼ばれる)は、機械エネルギーを蓄えるために使用されるコイル状のバネです。時計、玩具、その他エネルギー貯蔵を必要とする機器に広く使用されています。これらのゼンマイは、手巻きまたは機械巻きで巻き上げられ、エネルギーを放出することで機械装置に動力を与えます。

ねじりばねは、トルクまたは回転力に耐えるように設計されています。これらのばねは、クリップ、スイッチ、ガレージドアなど、回転力が加わるその他の装置によく使用され、ねじりによって反作用力を提供します。

真鍮スプリングは真鍮素材で作られており、優れた耐食性と導電性を備えています。電気スイッチや端子など、耐食性や導電性が求められる用途によく使用されます。

ワイヤーフォーミングには、金属線を曲げて様々な形状に成形するバネや部品が含まれます。これらは特定の用途に合わせてカスタム設計されており、特殊な機械装置や電子機器に適合する複雑な形状に加工することができます。

直接の見積もりと製品情報を入手してください。お問い合わせには 24 時間 365 日対応いたします。

info@makeway-llc.com

+86 755 28459980

中国広東省深圳市龍崗区平安大道1号華南城ビル13号1510号室