We specialize in manufacturing top-quality brass springs,delivering exceptional performance and reliability for your projects.From design to production,every step is meticulously controlled to ensure we provide the perfect solution for you.Whether you need high conductivity or durability,our brass springs meet the stringent demands of various applications

Brass Specifications:MK-BS-CS01、MK-BS-CS02、MK-BS-CS03、MK-BS-CS04、MK-BS-CS05、MK-BS-CS06

Brass springs are used in devices like switches,connectors,and terminals due to their conductivity and non-magnetic properties.

Ideal for corrosion-resistant environments,brass springs are found in valves,pumps, and pipe fittings.

Used in fuel systems and exposed components for their corrosion resistance.

Brass springs offer durability and conductivity in sensors and control systems.

Brass springs add both function and elegance to high-end items with their golden-yellow color.

We have the capability to provide our customers with custom brass springs to meet nearly any specification

We offer professional brass spring solutions designed to help you achieve optimal performance and reliability.Whether you need high elasticity,excellent corrosion resistance,or precise dimensions,we provide customized brass springs to meet your diverse needs.

Choose our brass spring solutions to enhance your product’s performance.Contact us today for more detailed information and professional advice!

With a series of rigorous tests and professional technical support, we are confident in the quality of our brass springs. We are committed to providing customers with high-performance, durable, and reliable brass springs, ensuring their stable operation in complex environments.

If you are interested in our brass spring products or have any questions, feel free to contact us. We are dedicated to serving you!

Material Analysis:

The composition of brass directly impacts the performance of the spring. Through material analysis,we ensure that the brass used in our springs meets industry standards,offering superior corrosion resistance and conductivity.

Tensile and Compression Testing:

The modulus of elasticity of brass springs determines their response to tension and compression.During testing,we evaluate how the spring performs under different loads to ensure it can withstand repeated loading and unloading in real-world applications.

부식 저항성 테스트:

Brass springs are often used in humid or corrosive environments.We conduct tests like salt spray testing to simulate actual working conditions and verify the spring’s resistance to corrosion in harsh environments.

Fatigue Testing:

Springs may fail due to fatigue when subjected to repeated loads over time.We conduct fatigue tests by repeatedly loading and unloading the spring to ensure that the fatigue life of our brass springs meets the required standards.

Tailored for your precision needs! We specialize in manufacturing brass springs that offer excellent corrosion resistance and conductivity, perfect for various electronic, electrical, and industrial applications. No matter the size or shape you require, we provide high-precision custom services to ensure each spring fits your design needs perfectly.

Enhance the performance of your products by choosing us for high-quality brass spring solutions! Contact us for custom orders and enjoy professional service with fast delivery!

If you have any other specific questions about brass springs or need more detailed answers, please feel free to contact us!

Brass springs are not typically used for high-stress or high-temperature applications.While they are durable and corrosion-resistant,they lack the strength of steel or other alloys under heavy loads or extreme temperatures.For such conditions,materials like alloy steel or stainless steel are more suitable.

Yes, brass springs are well-suited for outdoor use due to their corrosion resistance.However,in extremely harsh environments, additional surface treatments may be necessary to prolong their lifespan.

Brass springs generally require minimal maintenance. However,if they are exposed to harsh or corrosive environments,regular cleaning or protective coatings may be necessary to prevent surface oxidation or tarnishing.

Yes,brass springs can be customized in terms of size, shape,and tension based on specific requirements,including unique mechanical,electrical,or environmental needs.

초기 스프링 설계부터 제조 및 배송까지, 저희는 최고의 품질 관리와 엄격한 품질 보증을 통해 고객님의 프로젝트에 꼭 맞는 정밀 부품을 제공해 드립니다. 모든 솔루션은 고객님의 니즈에 맞춰 설계됩니다.

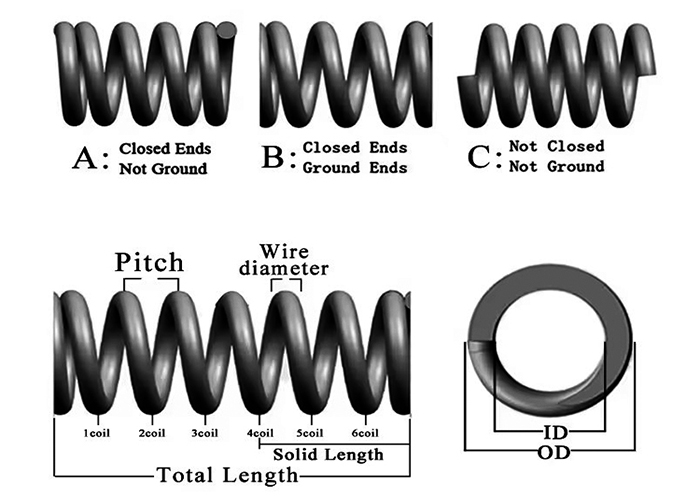

압축 스프링은 압축력에 저항하도록 설계된 일반적인 스프링 유형입니다. 이러한 스프링은 일반적으로 코일 형태로 되어 있으며 자동차 서스펜션, 산업 기계, 전자 장치 등의 응용 분야에 널리 사용됩니다.

다이 스프링은 고하중용으로 설계되었으며, 스탬핑 다이와 다이 세트에 주로 사용됩니다. 이 스프링은 일반적으로 고강도 합금강으로 제작되어 압축 저항성이 뛰어나고 수명이 깁니다.

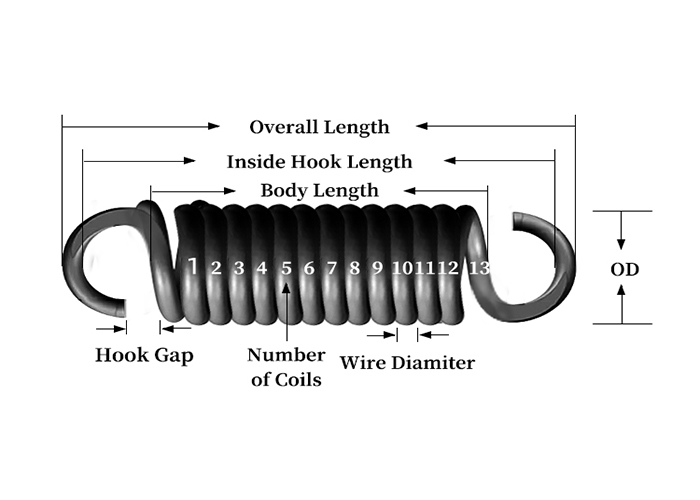

인장 스프링은 늘어났을 때 에너지를 저장하고, 놓으면 원래 모양으로 돌아옵니다. 도어락, 장난감, 기계 장치 등에 널리 사용됩니다. 인장 스프링은 일반적으로 양쪽 끝에 부착용 후크가 있습니다.

헤드리스 텐션 스프링은 일반 텐션 스프링과 유사하지만, 전통적인 후크나 끝부분이 없습니다. 이러한 스프링은 설계 요건을 충족하기 위해 특정 부착 방식이 필요한 용도에 사용됩니다.

시계 스프링(메인스프링이라고도 함)은 기계 에너지를 저장하는 데 사용되는 코일 스프링입니다. 시계, 장난감 등 에너지 저장이 필요한 장치에 널리 사용됩니다. 이 스프링은 수동 또는 기계적으로 감아서 에너지를 방출하여 기계 장치에 동력을 공급할 수 있습니다.

토션 스프링은 토크 또는 회전력을 견디도록 설계되었습니다. 이 스프링은 클립, 스위치, 차고 문 등 회전력이 가해지는 장치에 일반적으로 사용되며, 비틀림을 통해 반작용력을 제공합니다.

황동 스프링은 황동 소재로 제작되어 뛰어난 내식성과 전기 전도성을 제공합니다. 전기 스위치나 단자처럼 내식성이나 전기 전도성이 필요한 분야에 자주 사용됩니다.

와이어 성형에는 금속 와이어를 구부려 다양한 모양으로 만든 다양한 스프링과 부품이 포함됩니다. 이러한 와이어는 특정 용도에 맞춰 맞춤 설계되며, 특수 기계 또는 전자 장치에 맞게 복잡한 모양으로 제작될 수 있습니다.

직접 견적과 제품 정보를 받아보세요. 문의사항이 있으면 언제든지 연락주세요.

info@makeway-llc.com

+86 755 28459980

중국 광둥성 선전시 룽강구 핑안대도 1호 화난청 13동 1510호