Our engineers are trained to use cutting-edge techniques to craft tension spring for exceptional performance,durability,reliability,and cost-effectiveness.We also offer a wide range of tension spring sizes,and materials,allowing us to tailor our products to the unique needs of our customers.

탄소강 사양: MK-65MN-TCS01 、 MK-65MN-TCS02、 MK-65MN-TCS03、 MK-65MN-TCS04、 MK-65MN-TCS05、 MK-65MN-TCS06、 MK-65MN-TCS07、 MK-65MN-TS08、 MK-65MN-TCS09

304 스테인리스 스틸 사양:MK-304SS-TCS01 、MK-304SS-TCS02 、MK-304SS-TCS03 、MK-304SS-TCS04 、MK-304SS-TCS05、MK-304SS-TCS06、MK-304SS-TCS07、MK-304SS-TCS08

Hook-end extension springs are commonly used in various mechanical devices, particularly in scenarios where precise movement control or tension is required.

Hook-end extension springs are used to control the opening and closing of doors or to maintain the tension and position of certain components.

It provides elastic tension, allowing users to stretch and release for exercise or entertainment purposes.

Hook-end extension springs are used to keep doors and windows tightly closed or to control the opening angle. They also provide a gentle closing force to prevent the door from slamming shut.

Used to ensure stability of the equipment during operation or provide the necessary tension.

우리는 거의 모든 사양을 충족하는 맞춤형 압축 스프링을 고객에게 제공할 수 있는 역량을 갖추고 있습니다.

Your customers demand the highest quality springs for maximum load capacity and at Makeway Spring we have the springs you need. Our commitment to the highest quality spring for your application starts with the spring stock and doesn’t end until we pack and ship the last coil to complete your order.

재료 테스트:

We monitor every lot of wire material that is submitted for testing and prototyping to ensure the highest quality product.

치수 정확도:

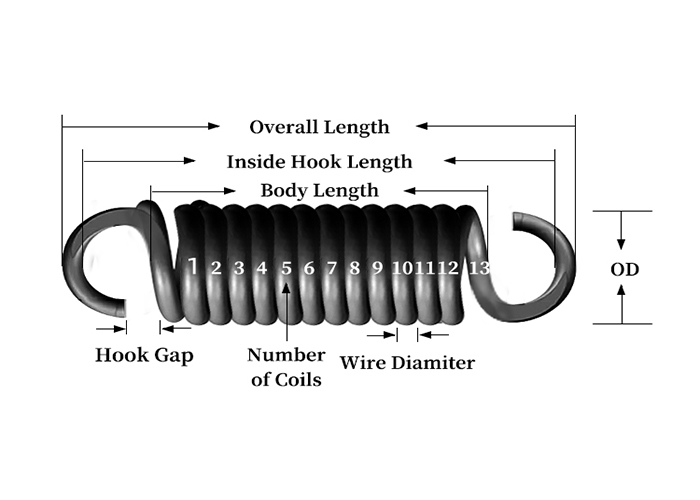

This involves measuring critical dimensions of the extension spring, such as wire diameter, outer diameter, length, and the number of active coils. This ensures that the spring conforms to your specified design requirements.

Load Testing:

This test involves subjecting the extension spring to various loads to verify that it can extend and retract without any deformation or failure. The load should be applied gradually to prevent sudden overloading

Elasticity and Stress Testing:

This test evaluates how well the spring returns to its original shape after being stretched. It measures factors like modulus of elasticity and yield strength to ensure the spring can handle the expected loads.

Fatigue Testing:

Extension springs are often subjected to repeated cycles of loading and unloading. Fatigue testing simulates these conditions to ensure the spring can withstand the anticipated number of cycles without failure

Load Testing:

This involves applying a load to the spring and measuring the corresponding deflection. This helps characterize the spring’s behavior under different loads.

Visual Inspection:

A visual examination of the spring is crucial to identify any surface defects, such as cracks, pitting, or other anomalies.

Tension springs store energy and resist pulling forces by elongating under load and returning to their original length. Typically made of stainless steel for durability and corrosion resistance, they’re vital in mechanical systems.

When selecting an extension spring with hooks, consider the following:

The tension an extension spring can handle depends on its material,wire diameter,number of coils,and design.Different specifications of extension springs are suited for various loads and applications.Manufacturers typically provide the maximum load specifications to ensure safe use.

The lifespan of an extension spring depends on factors such as usage frequency,applied tension,material,and environmental conditions.High-quality materials and proper surface treatments can extend the life of the spring.

Yes,if made from stainless steel or treated for corrosion resistance (e.g.,galvanized or coated),extension springs with hooks are suitable for outdoor or humid environments and can maintain performance for long period

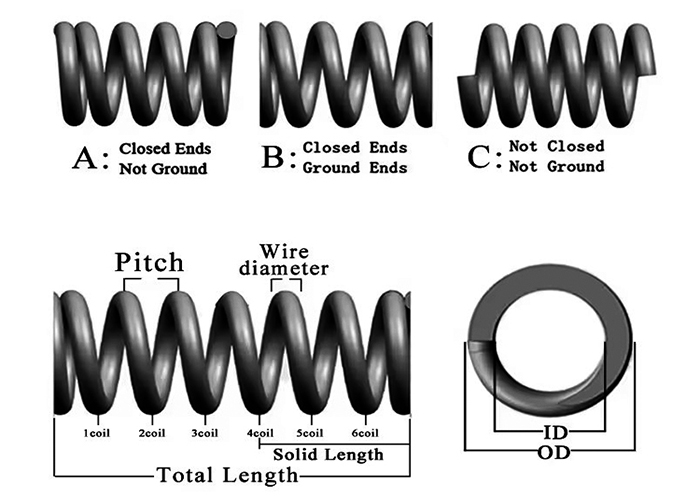

End treatment plays a crucial role in the functionality and durability of extension springs.Common methods include closed and ground ends,open ends with hooks or loops,or other specialized configurations.Proper finishing,such as shot peening or coating,can enhance corrosion resistance and surface quality.

Quality control is paramount in extension spring manufacturing.This includes dimensional inspections,load testing,stress and elasticity testing,material analysis,and visual inspections.Additionally, following relevant industry standards and adhering to specific customer requirements is crucial for producing reliable and consistent springs.

초기 스프링 설계부터 제조 및 배송까지, 저희는 최고의 품질 관리와 엄격한 품질 보증을 통해 고객님의 프로젝트에 꼭 맞는 정밀 부품을 제공해 드립니다. 모든 솔루션은 고객님의 니즈에 맞춰 설계됩니다.

압축 스프링은 압축력에 저항하도록 설계된 일반적인 스프링 유형입니다. 이러한 스프링은 일반적으로 코일 형태로 되어 있으며 자동차 서스펜션, 산업 기계, 전자 장치 등의 응용 분야에 널리 사용됩니다.

다이 스프링은 고하중용으로 설계되었으며, 스탬핑 다이와 다이 세트에 주로 사용됩니다. 이 스프링은 일반적으로 고강도 합금강으로 제작되어 압축 저항성이 뛰어나고 수명이 깁니다.

인장 스프링은 늘어났을 때 에너지를 저장하고, 놓으면 원래 모양으로 돌아옵니다. 도어락, 장난감, 기계 장치 등에 널리 사용됩니다. 인장 스프링은 일반적으로 양쪽 끝에 부착용 후크가 있습니다.

헤드리스 텐션 스프링은 일반 텐션 스프링과 유사하지만, 전통적인 후크나 끝부분이 없습니다. 이러한 스프링은 설계 요건을 충족하기 위해 특정 부착 방식이 필요한 용도에 사용됩니다.

시계 스프링(메인스프링이라고도 함)은 기계 에너지를 저장하는 데 사용되는 코일 스프링입니다. 시계, 장난감 등 에너지 저장이 필요한 장치에 널리 사용됩니다. 이 스프링은 수동 또는 기계적으로 감아서 에너지를 방출하여 기계 장치에 동력을 공급할 수 있습니다.

토션 스프링은 토크 또는 회전력을 견디도록 설계되었습니다. 이 스프링은 클립, 스위치, 차고 문 등 회전력이 가해지는 장치에 일반적으로 사용되며, 비틀림을 통해 반작용력을 제공합니다.

황동 스프링은 황동 소재로 제작되어 뛰어난 내식성과 전기 전도성을 제공합니다. 전기 스위치나 단자처럼 내식성이나 전기 전도성이 필요한 분야에 자주 사용됩니다.

와이어 성형에는 금속 와이어를 구부려 다양한 모양으로 만든 다양한 스프링과 부품이 포함됩니다. 이러한 와이어는 특정 용도에 맞춰 맞춤 설계되며, 특수 기계 또는 전자 장치에 맞게 복잡한 모양으로 제작될 수 있습니다.

직접 견적과 제품 정보를 받아보세요. 문의사항이 있으면 언제든지 연락주세요.

info@makeway-llc.com

+86 755 28459980

중국 광둥성 선전시 룽강구 핑안대도 1호 화난청 13동 1510호