In a fast-paced world, torsion springs are a vital component in many industries.

Their versatility and ability to store and release energy make them indispensable components in countless mechanical systems across different sectors.

Single Torsion Spring: MK-65MN-TS01 、MK-65MN-TS02

Double Torsion Spring: MK-65MN-TS03 、MK-65MN-TS04 、MK-65MN-TS05 、MK-65MN-TS06 、MK-65MN-TS07 、MK-65MN-TS08 、MK-65MN-TS09、MK-65MN-TS10 、MK-65MN-TS11 、MK-65MN-TS12 、MK-65MN-TS13 、MK-65MN-TS14 、MK-65MN-TS15 、MK-65MN-TS16 、MK-65MN-TS17 、MK-65MN-TS18

Custom-Shaped Torsion Spring: MK-65MN-TS19、MK-65MN-TS20、MK-65MN-TS21

Torsion springs are commonly used in automatic return door hinge systems,helping doors open and close smoothly while maintaining the desired position.

Torsion springs provide clamping force in items like clothespins and various clamps,holding objects securely in place.

Used in car doors,trunk lids, and other components that require a return function,such as seat angle adjusters.

Torsion springs are used in reset functions for electrical devices,such as camera shutters,clocks, and switches.

Torsion springs are employed in many spring-driven toys and devices to produce rotational movement or provide a return function.

We have the capability to provide our customers with custom torsion springs to meet nearly any specification

Reliable torsion spring operation requires the highest quality materials,precise machining,and efficient processes.Our state-of-the-art manufacturing facility,personal touch,and expertise ensure that your springs meet your exact specifications.Torsion springs are known for their reliability,and you can rely on us to bring your vision to life.

재료 테스트:

Although we use only the finest spring materials, we take nothing for granted. Every spring must meet our meticulous testing standards.

치수 정확도:

We measure down to the micrometer to ensure the dimensional accuracy that your product requires to not just meet operational standards, but exceed them.

운영 테스트:

We subject each spring to rigorous testing to ensure optimum performance and consistency.

Quality Assurance:

Our QA department is committed to delivering excellence and providing top-of-the-line quality products.

If you need a custom spring, our experts can help you design it. Your needs may depend on your industry,target market,or other factors.Whatever your particular needs,we can supply them at the highest level.

Ensuring a torsion spring’s compliance to your specifications requires a personal touch.We pride ourselves on working directly with you to make sure that your custom springs meet every requirement,every time. When quality and personal service come together,your custom springs come out right.

Our commitment to quality and service continues from product inception to the final roll-out of your torsion spring application.Have questions?We are here to help whether you are looking to R&D a single design or get a full line of products.Whatever your needs,our manufacturing capabilities deliver. Feel free to click below to get started.

We make torsion springs of any type or size that can serve a variety of industries.

A torsion spring, also known as a torque spring,is a type of coiled spring designed to store and release rotational force.When an external force is applied,the spring generates torque,and when released, it returns to its original position,providing return or rotational force.

The design of a torsion spring, including wire diameter,number of coils,arm length,and angle of rotation,directly impacts the torque it can provide and its working angle.These parameters can be adjusted to meet different mechanical requirements depending on the application.

Yes,torsion springs can be customized.Manufacturers can design and produce springs based on specific torque requirements,working angles,and space constraints provided by the customer

The manufacturing time can vary depending on the complexity and quantity of the order. However,Makeway Spring is known for its efficient production process, and we strive to deliver your springs within the agreed upon time frame.

Yes, Makeway Spring provides various finishing options for torsion springs,including heat treatment, plating,powder coating,and more,to enhance their durability and appearance.

The lifespan of a torsion spring depends on its material,usage frequency,load,and working environment.With proper design and maintenance,high-quality torsion springs can last for hundreds of thousands of cycles or even longer.

Of course,we have two warehouses in the United States. Whether you're located in the U.S. or Canada,Makeway Spring can deliver your torsion springs directly to your doorstep.

초기 스프링 설계부터 제조 및 배송까지, 저희는 최고의 품질 관리와 엄격한 품질 보증을 통해 고객님의 프로젝트에 꼭 맞는 정밀 부품을 제공해 드립니다. 모든 솔루션은 고객님의 니즈에 맞춰 설계됩니다.

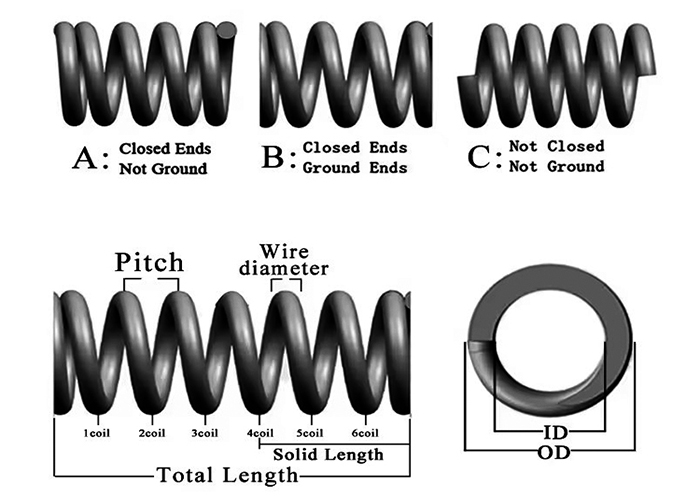

압축 스프링은 압축력에 저항하도록 설계된 일반적인 스프링 유형입니다. 이러한 스프링은 일반적으로 코일 형태로 되어 있으며 자동차 서스펜션, 산업 기계, 전자 장치 등의 응용 분야에 널리 사용됩니다.

다이 스프링은 고하중용으로 설계되었으며, 스탬핑 다이와 다이 세트에 주로 사용됩니다. 이 스프링은 일반적으로 고강도 합금강으로 제작되어 압축 저항성이 뛰어나고 수명이 깁니다.

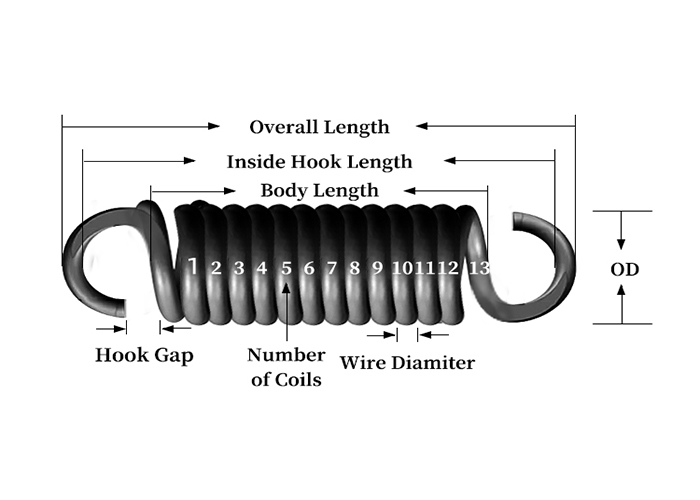

인장 스프링은 늘어났을 때 에너지를 저장하고, 놓으면 원래 모양으로 돌아옵니다. 도어락, 장난감, 기계 장치 등에 널리 사용됩니다. 인장 스프링은 일반적으로 양쪽 끝에 부착용 후크가 있습니다.

헤드리스 텐션 스프링은 일반 텐션 스프링과 유사하지만, 전통적인 후크나 끝부분이 없습니다. 이러한 스프링은 설계 요건을 충족하기 위해 특정 부착 방식이 필요한 용도에 사용됩니다.

시계 스프링(메인스프링이라고도 함)은 기계 에너지를 저장하는 데 사용되는 코일 스프링입니다. 시계, 장난감 등 에너지 저장이 필요한 장치에 널리 사용됩니다. 이 스프링은 수동 또는 기계적으로 감아서 에너지를 방출하여 기계 장치에 동력을 공급할 수 있습니다.

토션 스프링은 토크 또는 회전력을 견디도록 설계되었습니다. 이 스프링은 클립, 스위치, 차고 문 등 회전력이 가해지는 장치에 일반적으로 사용되며, 비틀림을 통해 반작용력을 제공합니다.

황동 스프링은 황동 소재로 제작되어 뛰어난 내식성과 전기 전도성을 제공합니다. 전기 스위치나 단자처럼 내식성이나 전기 전도성이 필요한 분야에 자주 사용됩니다.

와이어 성형에는 금속 와이어를 구부려 다양한 모양으로 만든 다양한 스프링과 부품이 포함됩니다. 이러한 와이어는 특정 용도에 맞춰 맞춤 설계되며, 특수 기계 또는 전자 장치에 맞게 복잡한 모양으로 제작될 수 있습니다.

직접 견적과 제품 정보를 받아보세요. 문의사항이 있으면 언제든지 연락주세요.

info@makeway-llc.com

+86 755 28459980

중국 광둥성 선전시 룽강구 핑안대도 1호 화난청 13동 1510호