Our engineers are trained to use cutting-edge techniques to craft tension spring for exceptional performance,durability,reliability,and cost-effectiveness.We also offer a wide range of tension spring sizes,and materials,allowing us to tailor our products to the unique needs of our customers.

Carbon Steel Specifications: MK-65MN-TCS01 、 MK-65MN-TCS02、 MK-65MN-TCS03、 MK-65MN-TCS04、 MK-65MN-TCS05、 MK-65MN-TCS06、 MK-65MN-TCS07、 MK-65MN-TS08、 MK-65MN-TCS09

304 Stainless Steel Specifications:MK-304SS-TCS01 、MK-304SS-TCS02 、MK-304SS-TCS03 、MK-304SS-TCS04 、MK-304SS-TCS05、MK-304SS-TCS06、MK-304SS-TCS07、MK-304SS-TCS08

Hook-end extension springs are commonly used in various mechanical devices, particularly in scenarios where precise movement control or tension is required.

Hook-end extension springs are used to control the opening and closing of doors or to maintain the tension and position of certain components.

It provides elastic tension, allowing users to stretch and release for exercise or entertainment purposes.

Hook-end extension springs are used to keep doors and windows tightly closed or to control the opening angle. They also provide a gentle closing force to prevent the door from slamming shut.

Used to ensure stability of the equipment during operation or provide the necessary tension.

We have the capability to provide our customers with custom compression springs to meet nearly any specification

Your customers demand the highest quality springs for maximum load capacity and at Makeway Spring we have the springs you need. Our commitment to the highest quality spring for your application starts with the spring stock and doesn’t end until we pack and ship the last coil to complete your order.

Material Testing:

We monitor every lot of wire material that is submitted for testing and prototyping to ensure the highest quality product.

Dimensional Accuracy:

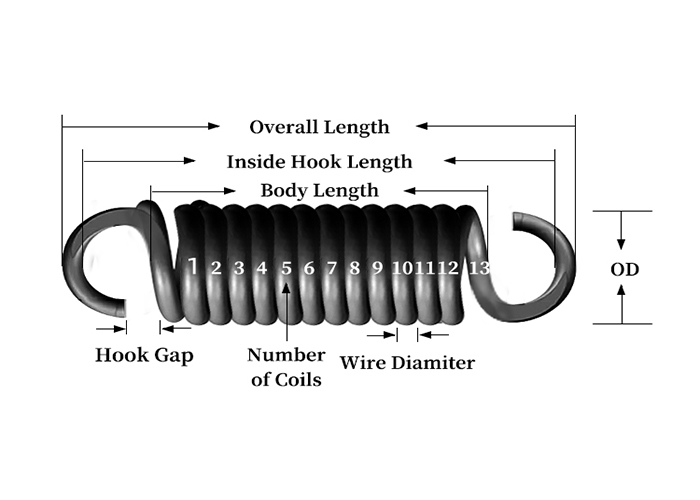

This involves measuring critical dimensions of the extension spring, such as wire diameter, outer diameter, length, and the number of active coils. This ensures that the spring conforms to your specified design requirements.

Load Testing:

This test involves subjecting the extension spring to various loads to verify that it can extend and retract without any deformation or failure. The load should be applied gradually to prevent sudden overloading

Elasticity and Stress Testing:

This test evaluates how well the spring returns to its original shape after being stretched. It measures factors like modulus of elasticity and yield strength to ensure the spring can handle the expected loads.

Fatigue Testing:

Extension springs are often subjected to repeated cycles of loading and unloading. Fatigue testing simulates these conditions to ensure the spring can withstand the anticipated number of cycles without failure

Load Testing:

This involves applying a load to the spring and measuring the corresponding deflection. This helps characterize the spring’s behavior under different loads.

Visual Inspection:

A visual examination of the spring is crucial to identify any surface defects, such as cracks, pitting, or other anomalies.

Tension springs store energy and resist pulling forces by elongating under load and returning to their original length. Typically made of stainless steel for durability and corrosion resistance, they’re vital in mechanical systems.

When selecting an extension spring with hooks, consider the following:

The tension an extension spring can handle depends on its material,wire diameter,number of coils,and design.Different specifications of extension springs are suited for various loads and applications.Manufacturers typically provide the maximum load specifications to ensure safe use.

The lifespan of an extension spring depends on factors such as usage frequency,applied tension,material,and environmental conditions.High-quality materials and proper surface treatments can extend the life of the spring.

Yes,if made from stainless steel or treated for corrosion resistance (e.g.,galvanized or coated),extension springs with hooks are suitable for outdoor or humid environments and can maintain performance for long period

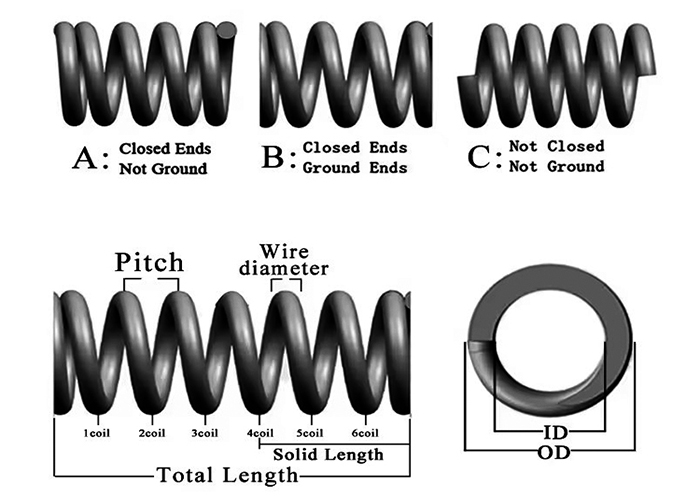

End treatment plays a crucial role in the functionality and durability of extension springs.Common methods include closed and ground ends,open ends with hooks or loops,or other specialized configurations.Proper finishing,such as shot peening or coating,can enhance corrosion resistance and surface quality.

Quality control is paramount in extension spring manufacturing.This includes dimensional inspections,load testing,stress and elasticity testing,material analysis,and visual inspections.Additionally, following relevant industry standards and adhering to specific customer requirements is crucial for producing reliable and consistent springs.

From the initial spring design to the manufacturing and delivery.Our best practices and quality assurance ensure you end up with the precise parts made just for your project. Every solution is designed for your needs.

Compression springs are a common type of spring designed to resist compressive forces. These springs are typically coiled and are widely used in applications like automotive suspensions, industrial machinery, and electronic devices.

Die springs are designed for high-load applications, commonly used in stamping dies and die sets. These springs are usually made of high-strength alloy steel, providing greater resistance to compression and longer service life.

Tension springs store energy when stretched and return to their original shape when released. They are commonly used in applications such as door locks, toys, and mechanical devices. Tension springs typically have hooks on both ends for attachment.

Headless tension springs are similar to regular tension springs but lack traditional hooks or ends. These springs are used in applications requiring specific attachment methods to meet design requirements.

Clock springs, also known as mainsprings, are coiled springs used to store mechanical energy. They are widely used in clocks, toys, and other devices that require energy storage. These springs can be wound manually or mechanically and then release energy to power mechanical devices.

Torsion springs are designed to withstand torque or rotational force. These springs are commonly used in clips, switches, garage doors, and other devices where rotational force is applied, providing a counteracting force by twisting.

Brass springs are made from brass material, offering excellent corrosion resistance and electrical conductivity. They are often used in applications requiring corrosion resistance or electrical conductivity, such as electrical switches and terminals.

Wire forming include various springs and parts formed by bending metal wire into shapes. These are custom-designed for specific applications and can be made into complex shapes to fit unique mechanical or electronic devices.

Obtain firsthand quotes and product information; we are available 24/7 to assist you with any inquiries.

info@makeway-llc.com

+86 755 28459980

Room 1510, Building 13 Huanancheng, No.1 Ping'an Avenue, Longgang District, Shenzhen, Guangdong, China