At Makeway Spring,we manufacture custom headless extension springs,including small and conical types,for various industrial uses.We also offer a wide inventory.Contact us for more details.

304 Stainless Steel Specifications:MK-304SS-TSH01、MK-304SS-TSH02、MK-304SS-TSH03

Headless tension springs,with their precise tension, are commonly used in precision machinery or electronic instruments.

Headless tension springs provide critical tension or resetting functions,helping to maintain the positioning of components.

These springs, due to their compact design, can fit into limited internal spaces and return to their original position after being pressed.

Headless tension springs can provide sufficient return force,ensuring that equipment components reliably reset.

In automated production lines and industrial equipment, headless extension springs are commonly used to provide tension or resetting functions.

We have the capability to provide our customers with custom Tension springs to meet nearly any specification

Our high-performance coils are engineered to thrive in even the most challenging environments,providing superior performance when it matters most.We source only the finest materials,meticulously chosen for their purity,reliability,and biocompatibility.

At Makeway Spring ,we’re not just about springs;we’re all about quality.Our commitment to ensuring the highest standards for tension spring begins with comprehensive testing.From materials to dimensional accuracy and operational performance,we leave no stone unturned to guarantee your product’s excellence from the very start.

Material Testing:

Your best product deserves the finest materials. We offer a wide range of materials and test each one so that you can be sure your product is its best from start to finish.

Dimensional Accuracy:

Measuring is more than meets the eye. We use state of the art measuring tools to ensure accuracy down to the micrometer.

Operational Testing:

Before we even consider shipping your springs to you, each one is subjected to rigorous testing at each point in the production process, guaranteeing each one will perform at the highest level.

From the type of material to the diameter and end types, we have what you need to create your custom springs to ensure optimal performance. If you don’t have exactly what you need in the springs in stock – choose our custom manufacturing services and get the perfect solution for your unique situation.

Our commitment to quality and customer satisfaction is unmatched,and we strive to provide exceptional service at every step of the way.Whether you need a single custom coil or a large order,we have the expertise and experience to deliver the results you need.Feel free to click below to request a quote or contact us for design assistance.

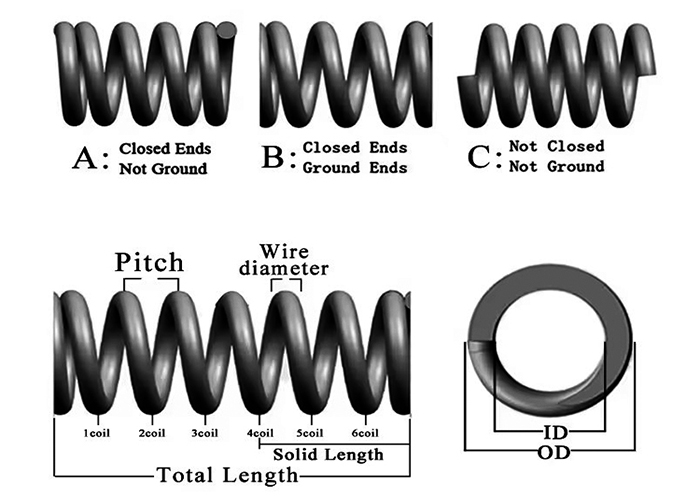

Compression springs are designed to create resistance to a compressive force.We’ve helped companies design, test,and manufacture compression springs for a wide variety of industries.Reach out to one of our engineers today and let’s get your project started.

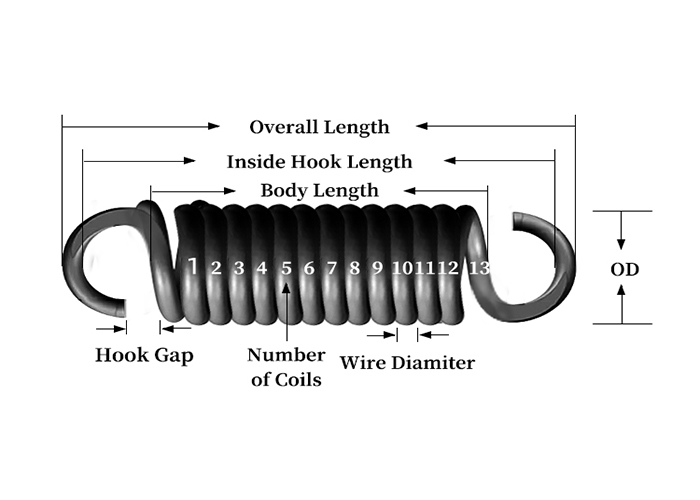

A headless tension spring is a type of tension spring without hooks or looped ends.Instead of having specific end fittings,it has open ends that can be directly attached to other components or structures.These springs are used for applications where a simpler connection is needed.

Headless tension springs are typically installed by attaching the open ends to the desired components or fixtures.The installation process may involve inserting the ends into designated slots or connecting them with other mechanical fasteners,depending on the application.

From the initial spring design to the manufacturing and delivery.Our best practices and quality assurance ensure you end up with the precise parts made just for your project. Every solution is designed for your needs.

Compression springs are a common type of spring designed to resist compressive forces. These springs are typically coiled and are widely used in applications like automotive suspensions, industrial machinery, and electronic devices.

Die springs are designed for high-load applications, commonly used in stamping dies and die sets. These springs are usually made of high-strength alloy steel, providing greater resistance to compression and longer service life.

Tension springs store energy when stretched and return to their original shape when released. They are commonly used in applications such as door locks, toys, and mechanical devices. Tension springs typically have hooks on both ends for attachment.

Headless tension springs are similar to regular tension springs but lack traditional hooks or ends. These springs are used in applications requiring specific attachment methods to meet design requirements.

Clock springs, also known as mainsprings, are coiled springs used to store mechanical energy. They are widely used in clocks, toys, and other devices that require energy storage. These springs can be wound manually or mechanically and then release energy to power mechanical devices.

Torsion springs are designed to withstand torque or rotational force. These springs are commonly used in clips, switches, garage doors, and other devices where rotational force is applied, providing a counteracting force by twisting.

Brass springs are made from brass material, offering excellent corrosion resistance and electrical conductivity. They are often used in applications requiring corrosion resistance or electrical conductivity, such as electrical switches and terminals.

Wire forming include various springs and parts formed by bending metal wire into shapes. These are custom-designed for specific applications and can be made into complex shapes to fit unique mechanical or electronic devices.

Obtain firsthand quotes and product information; we are available 24/7 to assist you with any inquiries.

info@makeway-llc.com

+86 755 28459980

Room 1510, Building 13 Huanancheng, No.1 Ping'an Avenue, Longgang District, Shenzhen, Guangdong, China