We specialize in manufacturing top-quality brass springs,delivering exceptional performance and reliability for your projects.From design to production,every step is meticulously controlled to ensure we provide the perfect solution for you.Whether you need high conductivity or durability,our brass springs meet the stringent demands of various applications

Brass Specifications:MK-BS-CS01、MK-BS-CS02、MK-BS-CS03、MK-BS-CS04、MK-BS-CS05、MK-BS-CS06

Brass springs are used in devices like switches,connectors,and terminals due to their conductivity and non-magnetic properties.

Ideal for corrosion-resistant environments,brass springs are found in valves,pumps, and pipe fittings.

Used in fuel systems and exposed components for their corrosion resistance.

Brass springs offer durability and conductivity in sensors and control systems.

Brass springs add both function and elegance to high-end items with their golden-yellow color.

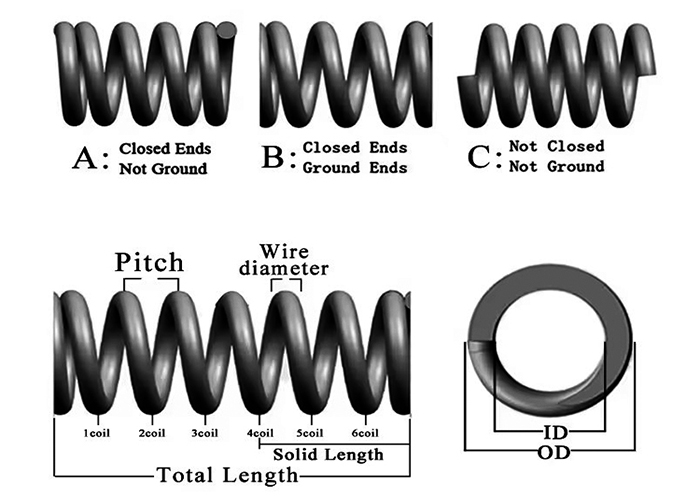

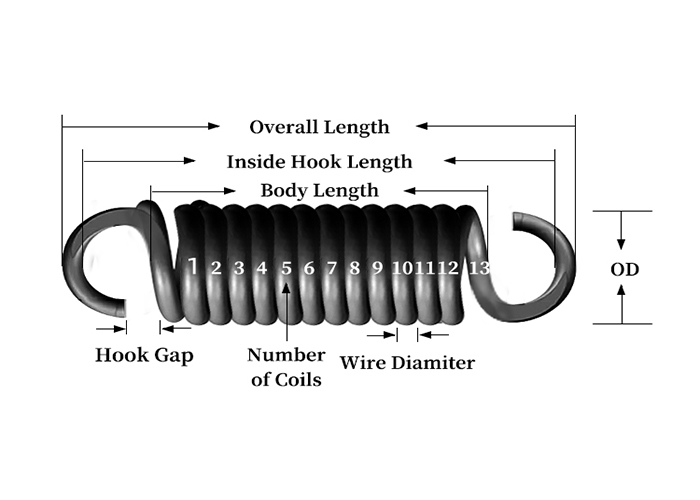

We have the capability to provide our customers with custom brass springs to meet nearly any specification

We offer professional brass spring solutions designed to help you achieve optimal performance and reliability.Whether you need high elasticity,excellent corrosion resistance,or precise dimensions,we provide customized brass springs to meet your diverse needs.

Choose our brass spring solutions to enhance your product’s performance.Contact us today for more detailed information and professional advice!

With a series of rigorous tests and professional technical support, we are confident in the quality of our brass springs. We are committed to providing customers with high-performance, durable, and reliable brass springs, ensuring their stable operation in complex environments.

If you are interested in our brass spring products or have any questions, feel free to contact us. We are dedicated to serving you!

材料分析:

The composition of brass directly impacts the performance of the spring. Through material analysis,we ensure that the brass used in our springs meets industry standards,offering superior corrosion resistance and conductivity.

Tensile and Compression Testing:

The modulus of elasticity of brass springs determines their response to tension and compression.During testing,we evaluate how the spring performs under different loads to ensure it can withstand repeated loading and unloading in real-world applications.

Corrosion Resistance Testing:

Brass springs are often used in humid or corrosive environments.We conduct tests like salt spray testing to simulate actual working conditions and verify the spring’s resistance to corrosion in harsh environments.

疲劳测试:

Springs may fail due to fatigue when subjected to repeated loads over time.We conduct fatigue tests by repeatedly loading and unloading the spring to ensure that the fatigue life of our brass springs meets the required standards.

Tailored for your precision needs! We specialize in manufacturing brass springs that offer excellent corrosion resistance and conductivity, perfect for various electronic, electrical, and industrial applications. No matter the size or shape you require, we provide high-precision custom services to ensure each spring fits your design needs perfectly.

Enhance the performance of your products by choosing us for high-quality brass spring solutions! Contact us for custom orders and enjoy professional service with fast delivery!

If you have any other specific questions about brass springs or need more detailed answers, please feel free to contact us!

Brass springs are not typically used for high-stress or high-temperature applications.While they are durable and corrosion-resistant,they lack the strength of steel or other alloys under heavy loads or extreme temperatures.For such conditions,materials like alloy steel or stainless steel are more suitable.

Yes, brass springs are well-suited for outdoor use due to their corrosion resistance.However,in extremely harsh environments, additional surface treatments may be necessary to prolong their lifespan.

Brass springs generally require minimal maintenance. However,if they are exposed to harsh or corrosive environments,regular cleaning or protective coatings may be necessary to prevent surface oxidation or tarnishing.

Yes,brass springs can be customized in terms of size, shape,and tension based on specific requirements,including unique mechanical,electrical,or environmental needs.

从最初的弹簧设计到制造和交付,我们秉承最佳实践和质量保证,确保您最终获得专为您的项目量身定制的精密零件。每个解决方案都根据您的需求量身定制。

获取第一手报价和产品信息;我们全天候为您提供帮助,解答您的任何疑问。

info@makeway-llc.com

+86 755 28459980

中国广东省深圳市龙岗区平安大道1号华南城13栋1510室